Golf Mk5

| Adjusting valve timing |

| Special tools and workshop equipment required |

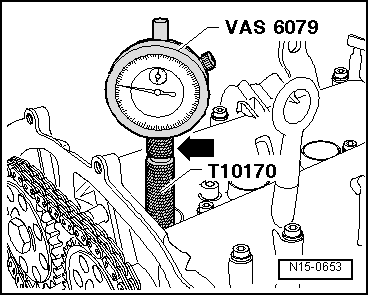

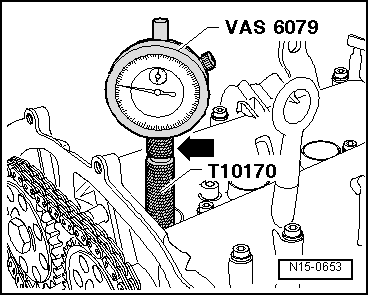

| t | Dial gauge -VAS 6079- |

| t | Puller -T10094 A- |

| t | Dial gauge adapter -T10170- |

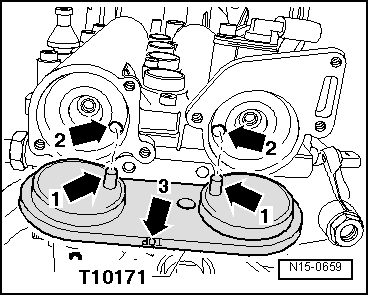

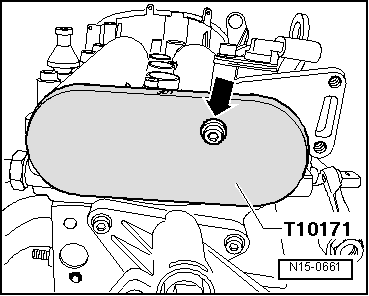

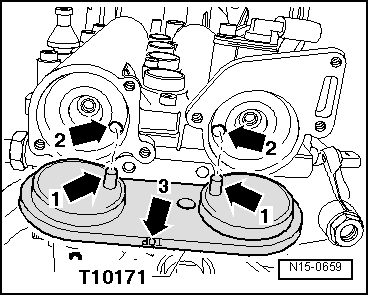

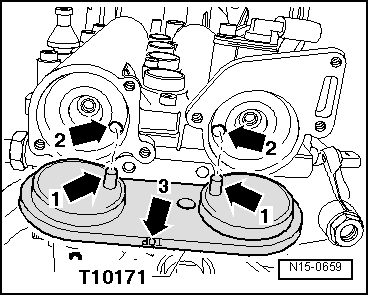

| t | Camshaft clamp -T10171- |

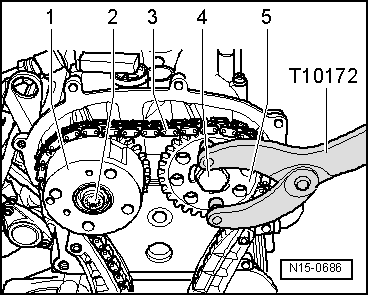

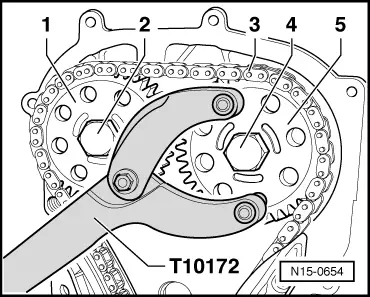

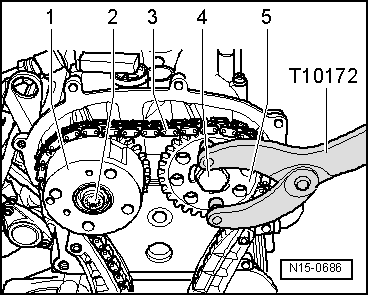

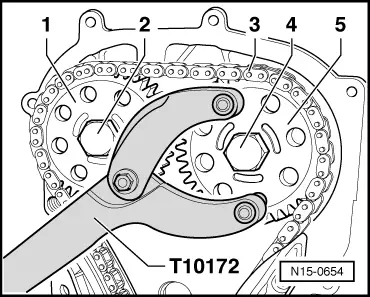

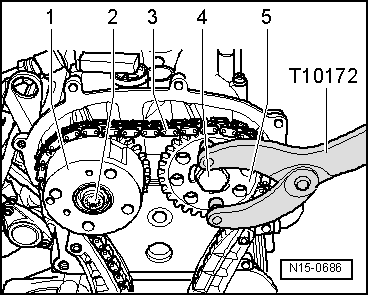

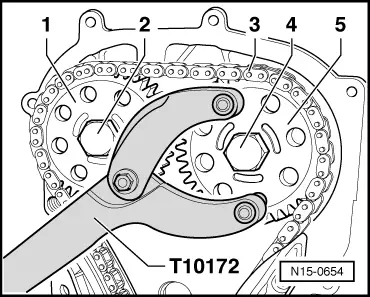

| t | Counterhold tool -T10172- |

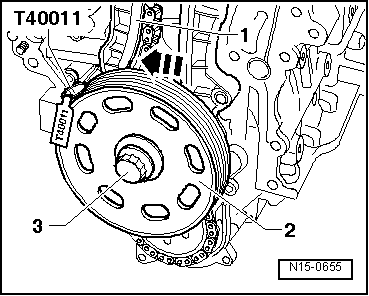

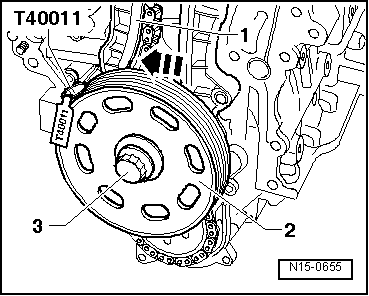

| t | Locking pin -T40011- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|