| –

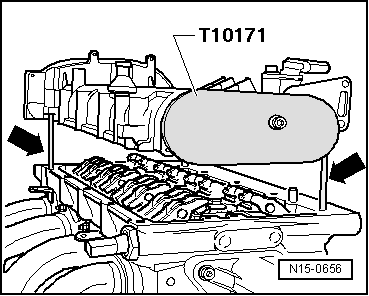

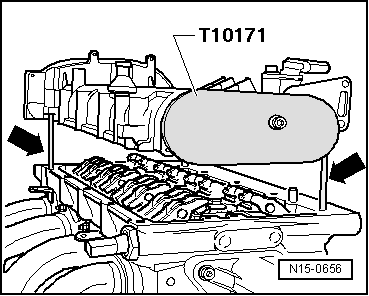

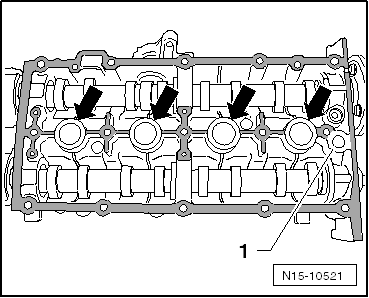

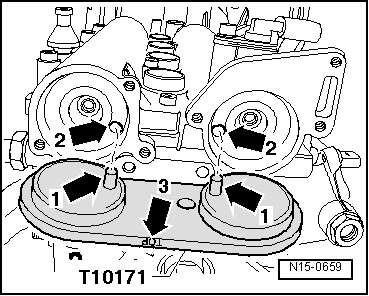

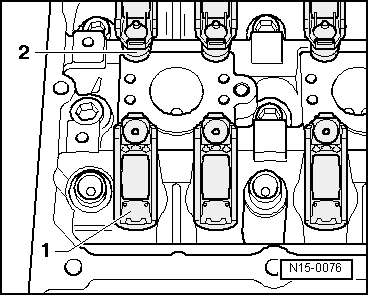

| Carefully fit camshaft housing vertically onto studs -arrows- and dowel pins from above. |

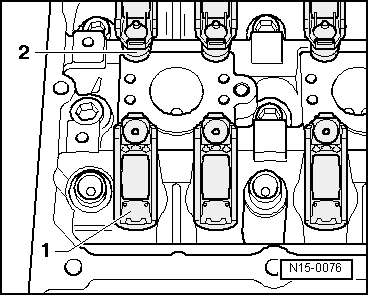

Note | Ensure that no oil residue can drip onto sealing surfaces. |

| –

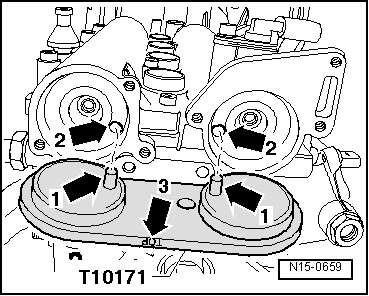

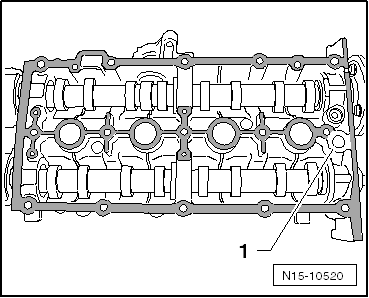

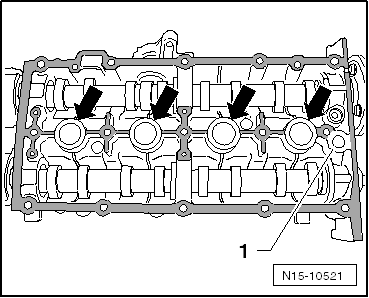

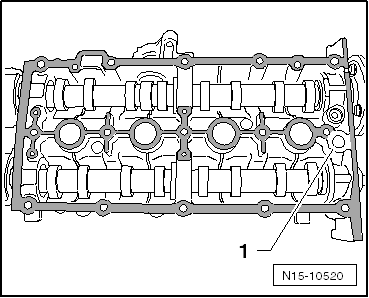

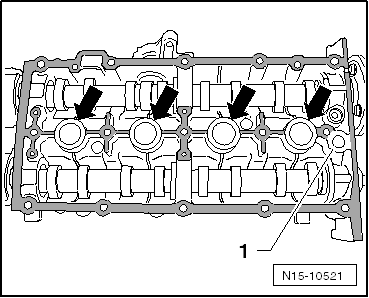

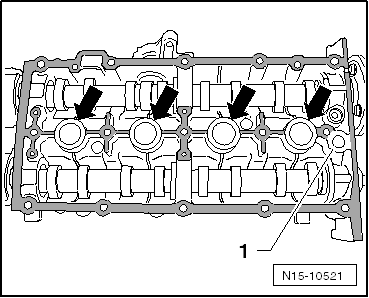

| Evenly tighten new camshaft housing securing bolts from inside to outside alternately and diagonally. |

| Ensure that camshaft housing is not canted. Specified torque: 10 Nm + turn 90° further. |

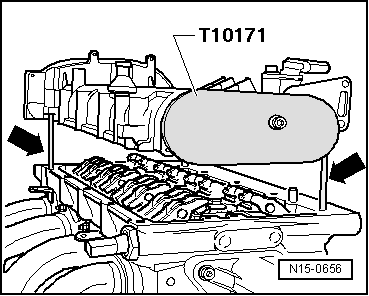

Note | Sealant must dry for approx. 30 minutes after camshaft housing is installed. |

| Further assembly is basically the reverse of the dismantling sequence. In the process, note the following: |

| t

| Fit fuel lines (engine codes BAG, BKG) → Chapter |

| t

| Fit fuel lines (engine codes BLF, BLN, BLP) → Chapter |

| t

| Install exhaust gas recirculation valve -N18- → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note