| –

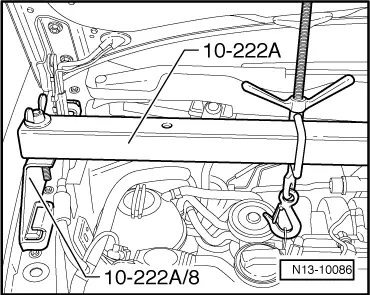

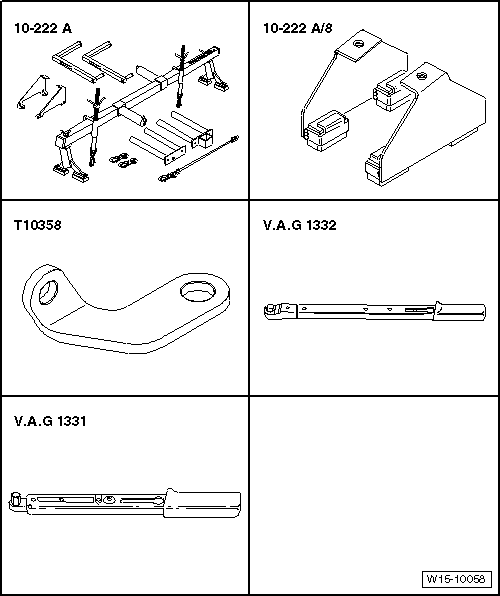

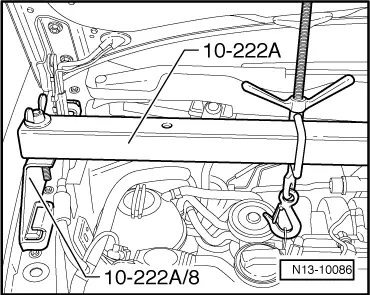

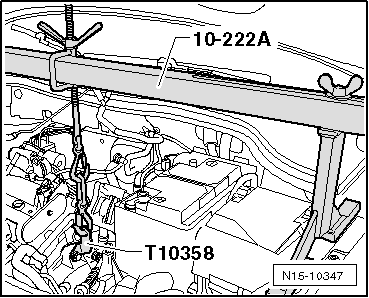

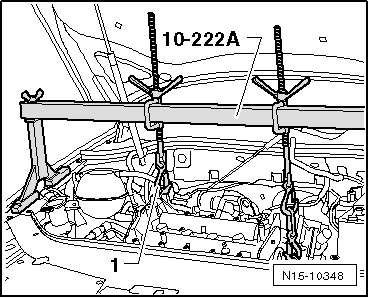

| Install support device -10 - 222 A- with adapter -10 - 222 A /8- as shown and hook into lifting eye. |

| Remove following components: |

| t

| Remove exhaust gas recirculation valve -N18- → Chapter |

| t

| Remove thermostat housing from cylinder head. |

| t

| Remove fuel lines (engine codes BAG, BKG) → Chapter |

| t

| Remove fuel lines (engine codes BLF, BLN, BLP) → Chapter |

| t

| Remove timing chain and chain drive for oil pump (engine codes BAG, BLP, BLF) → Chapter |

| t

| Remove timing chain and chain drive for oil pump (engine codes BKG, BLN) → Chapter |

|

|

|

Note

Note