Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route all the various lines (e.g. for fuel, hydraulics, activated charcoal filter system, coolant, refrigerant, brake fluid and vacuum) and electrical wiring in their original positions. |

| t

| To avoid damage to lines, ensure sufficient clearance to all moving or hot components. |

|

| –

| First check whether a coded radio is fitted. If so, obtain anti-theft coding. |

| –

| With the ignition switched off, disconnect battery earth strap. |

| –

| First remove main drive toothed belt → Chapter. |

| –

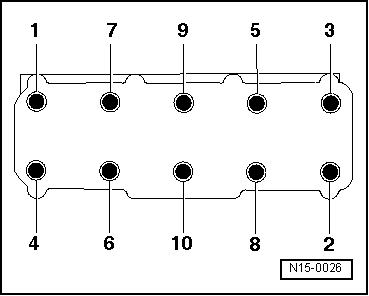

| Remove roller rocker fingers together with support elements and lay aside on a clean surface. |

| –

| Ensure that roller rocker fingers and support elements are not interchanged. |

WARNING | Steam may escape when expansion tank is opened. Wear eye protection and protective clothing to avoid eye injuries and scalding. Cover cap with cloth and open carefully. |

|

| –

| Open and close expansion tank cap to release pressure in cooling system. |

| –

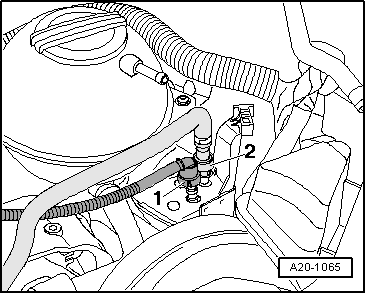

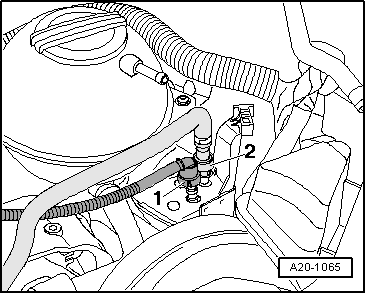

| Loosen hose clips and pull coolant hoses off coolant thermostat housing. |

| –

| Remove oil dipstick guide tube. |

WARNING | Fuel supply lines are under pressure! Wear eye protection and gloves to avoid injuries and skin contact. Before loosening hose connections, wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

Note

Note

Note

Note