Note | t

| Before carrying out further work, disconnect battery earth strap. First check whether a coded radio is fitted. Obtain anti-theft coding first if necessary. |

| t

| The engine is removed downwards together with the gearbox. |

| t

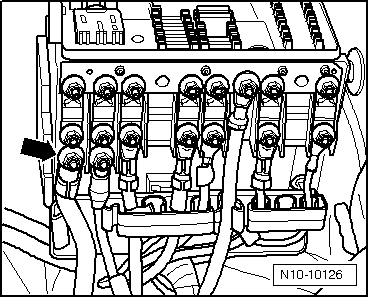

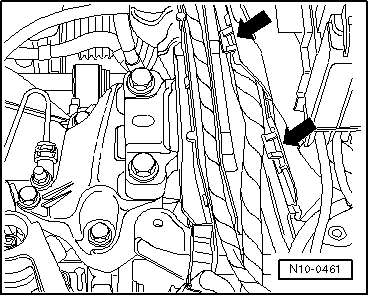

| All cable ties which are opened or cut through when the engine is removed must be replaced in the same position when the engine is installed. |

Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

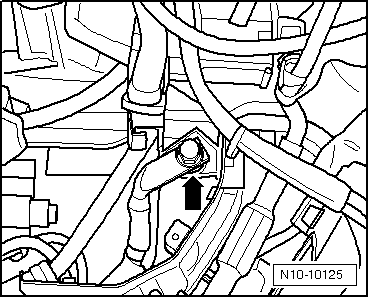

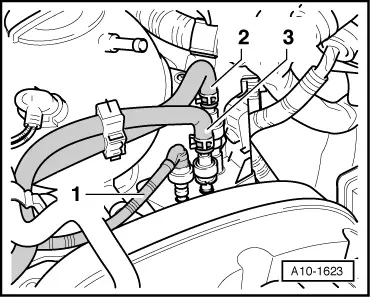

| Route all the various lines (e.g. for fuel, hydraulics, activated charcoal filter system, coolant and refrigerant, brake fluid and vacuum) and electrical wiring in their original positions. |

| t

| To avoid damage to lines, ensure sufficient clearance to all moving or hot components. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING