Golf Mk5

| Assembly overview - fuel tank |

| 1 - | Supply line |

| q | Black |

| q | Check for secure seating. |

| 2 - | Return line |

| q | Blue |

| q | Check for secure seating. |

| 3 - | Seal |

| q | Renew. |

| q | When installing, fit dry in fuel tank opening. |

| q | Moisten with fuel only when installing flange. |

| 4 - | Fuel delivery unit |

| q | Removing and installing → Chapter |

| q | If fuel delivery unit was renewed, adapt engine control unit to fuel pump → Vehicle diagnostic tester„Guided functions“ |

| q | Checking fuel pump → Chapter. |

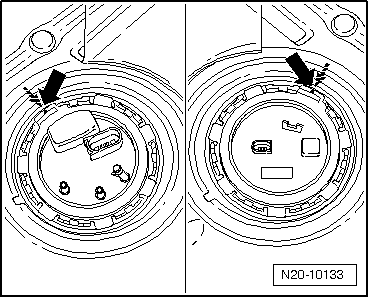

| q | Note installation position on fuel tank → Fig.. |

| q | With fuel gauge sender -G-. |

| q | Removing and installing fuel gauge sender → Chapter. |

| q | Clean strainer if soiled. |

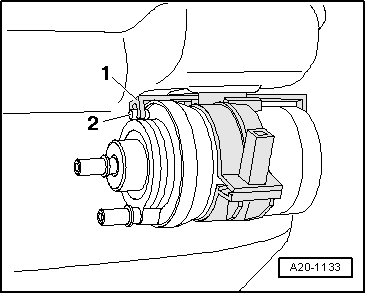

| 5 - | Locking ring, 110 Nm |

| q | Check for secure seating. |

| q | Remove and install using wrench -T10202-. |

| 6 - | Breather line |

| q | From gravity valve to activated charcoal filter |

| q | Clip onto bracket in wheel housing |

| q | To pull off, press release button on connection. |

| 7 - | Cap |

| q | Renew if damaged |

| 8 - | Securing bolt |

| 9 - | Tank flap unit |

| q | With rubber cup. |

| q | Removing and installing → General body repairs, exterior; Rep. gr.55. |

| 10 - | Earth connection |

| q | Check for secure seating. |

| 11 - | 10 Nm |

| 12 - | Protective plate |

| q | For fuel filler neck |

| q | Ensure that earth connection is securely seated |

| 13 - | 10 Nm |

| 14 - | Cable retainer |

| q | Clipped onto protective plate |

| 15 - | Fuel gauge sender 2 -G169- |

| q | Removing and installing → Chapter |

| q | Note installation position on fuel tank → Fig.. |

| 16 - | Suction-jet pump |

| q | Clipped onto fuel gauge sender 2 -G169- |

| q | Removing and installing → Chapter |

| 17 - | Fuel tank |

| q | When removing, support using engine and gearbox jack -V.A.G 1383 A-. |

| q | Removing and installing → Chapter |

| 18 - | Securing strap |

| q | Note installation position. |

| 19 - | 25 Nm |

| q | Renew. |

| q | To secure the securing straps for the fuel tank, only bolts with loose washers must be used. If different bolts are used, the securing straps might twist during tightening. Bolts → ETKA (electronic parts catalogue). |

| 20 - | Heat shield |

| q | Riveted to exhaust pipe mounting |

| 21 - | 3 Nm |

| 22 - | Breather line |

| q | White |

| q | From activated charcoal filter to activated charcoal filter solenoid valve 1 -N80- |

| q | Do not kink. |

| q | To pull off, press release button on connection. |

| q | Clipped onto fuel tank. |

| 23 - | Vacuum line |

| q | Green |

| q | From fuel system diagnosis pump -V144- to intake manifold. |

| q | Clipped onto fuel tank. |

| q | Check for secure seating. |

| 24 - | Supply line |

| q | To fuel rail. |

| 25 - | Fuel filter |

| q | Installation position: arrow indicates direction of flow. |

| q | Removing and installing → Chapter |

| 26 - | 8 Nm |

|

|

Note

Note