| Component | Specified torque |

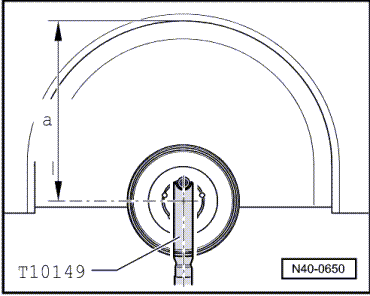

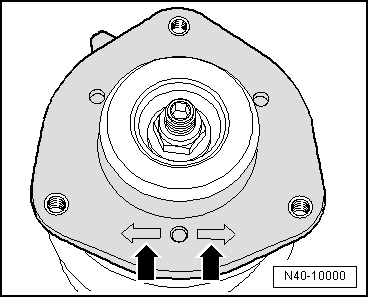

| Suspension strut to wheel bearing housing | 70 Nm + 90° |

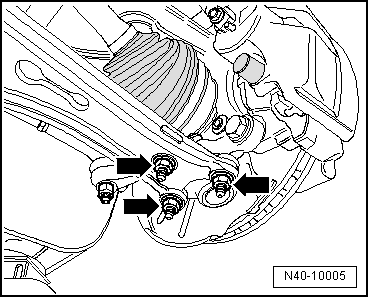

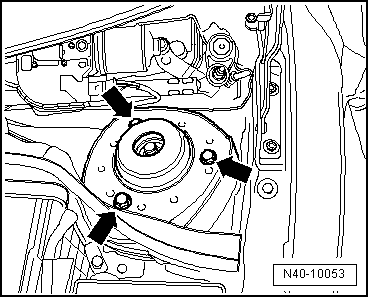

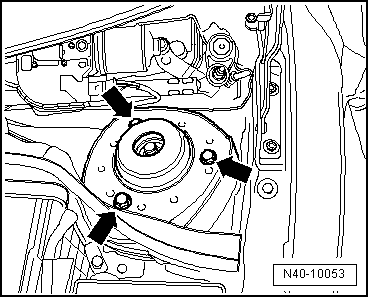

| Suspension strut to body (suspension turret) | 15 Nm + 90° |

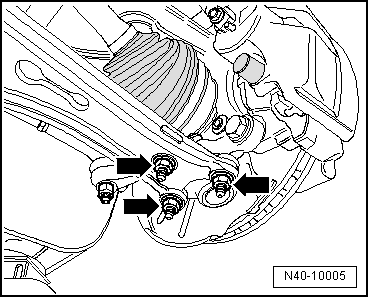

| Swivel joint to cast steel suspension link | 60 Nm |

| Swivel joint to sheet steel or forged aluminium suspension link | 100 Nm |

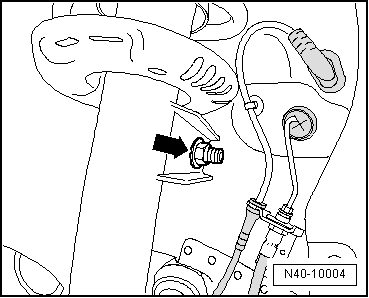

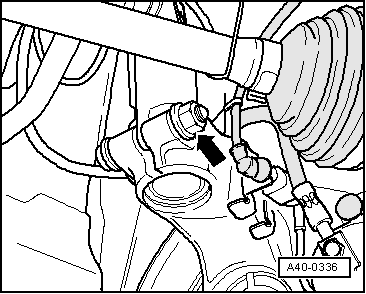

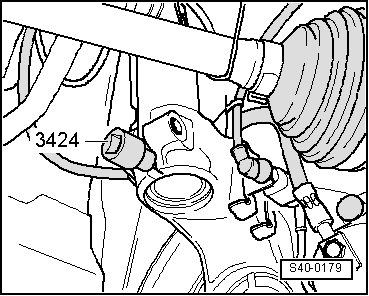

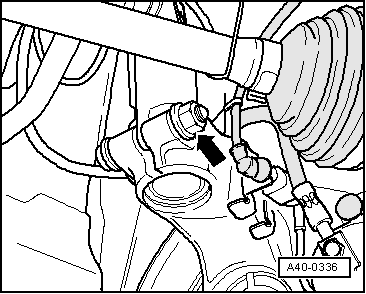

Coupling rod to suspension strut| t

| Counterhold on multi-point socket of joint pin |

| 65 Nm |

| Drive shaft to wheel hub „hexagon bolt“ | 200 Nm + 180° |

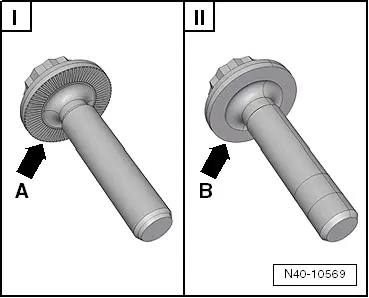

| Drive shaft to wheel hub „twelve-point head bolt with ribbing“ | 70 Nm + 90° |

| Drive shaft to wheel hub „twelve-point head bolt without ribbing“ | 200 Nm + 180° |

Note

Note

Caution

Caution WARNING

WARNING