| –

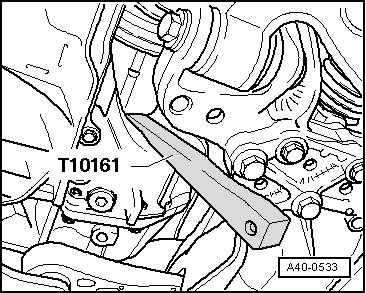

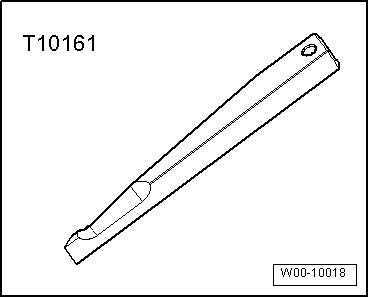

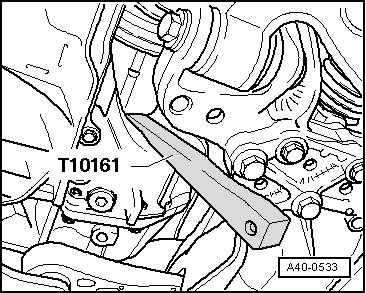

| Insert wedge-T10161- between gearbox housing and triple roller joint. |

| –

| Press inner joint out of gearbox by striking wedge -T10161- with a hammer. |

| –

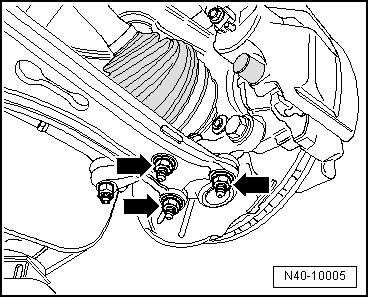

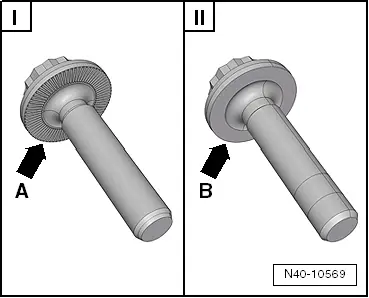

| Fit new retaining ring into groove of joint pin. |

| –

| Mesh outer and inner splines of joint body and gearbox. |

| –

| Slide drive shaft into joint body to stop by hand. |

| –

| Now »suddenly« push joint body into gearbox. |

| The joint travel can be used for the »sudden push«. Do not, however, pull the drive shaft too far out of the joint body. |

Note | Never use a hammer or other striking tool! |

| –

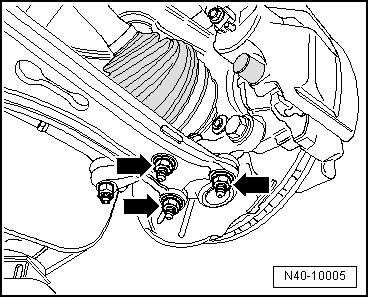

| Check that drive shaft is seated securely in gearbox by pulling on joint body against resistance of retaining ring. |

| For this check, pull only on joint body and not on drive shaft. |

| –

| Guide outer joint into wheel hub splines as far as possible. |

|

|

|

Note

Note

Note

Note

Caution

Caution