| –

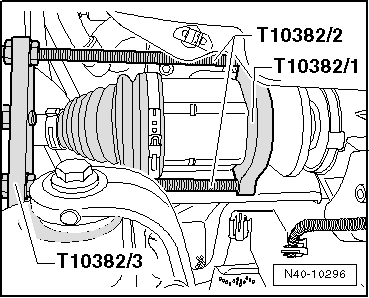

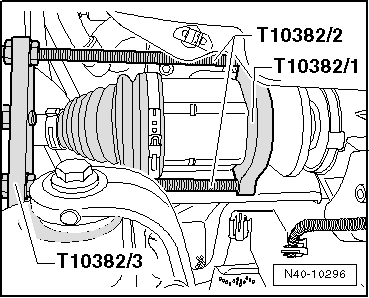

| Set up drive shaft puller -T10382- and pull out drive shaft. |

| –

| Remove drive shaft from vehicle. |

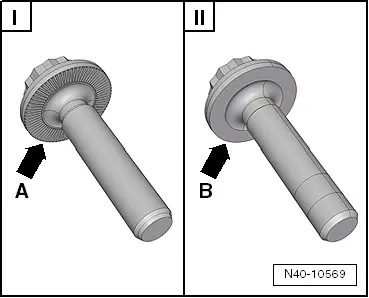

| Remove any paint residue and/or corrosion on thread and splines of outer joint. |

| –

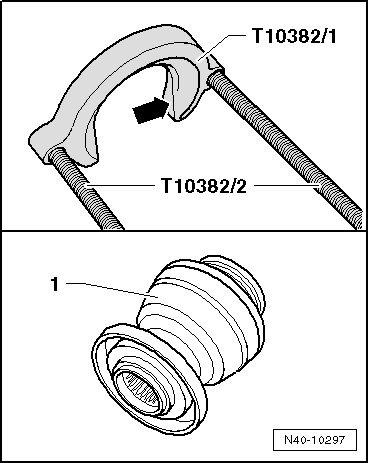

| Insert new retaining ring in groove in stub shaft on gearbox. |

| –

| Lightly grease splines of stub shaft with universal grease -G 060 735 A2- |

| –

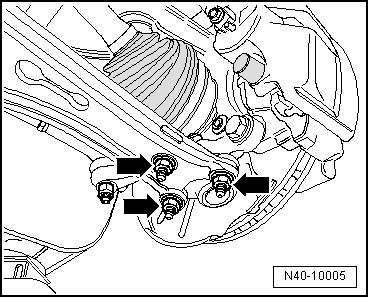

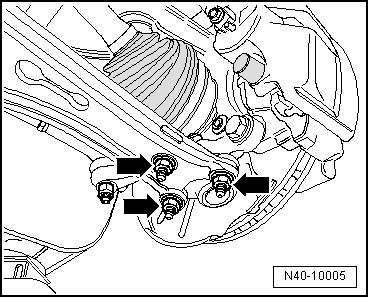

| Mesh outer and inner splines of gearbox and constant velocity slip joint. |

| –

| Slide drive shaft into constant velocity joint to stop by hand. |

| –

| Now push constant velocity joint onto stub shaft of gearbox with a »sudden, hard push«. |

Note | Never use a hammer or other striking tool! |

| –

| Check that constant velocity slip joint is seated securely by pulling on constant velocity joint against resistance of retaining ring. |

Caution | For this check, pull only on constant velocity slip joint, not on drive shaft. |

|

| –

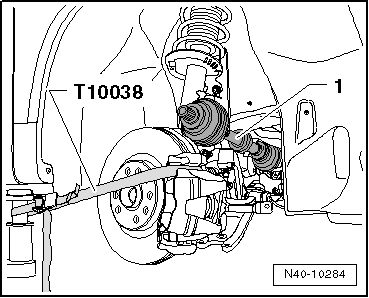

| Detach tensioning strap -T10038-. |

| –

| Guide outer joint into wheel hub splines as far as possible. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution