Golf Mk5

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Specified torque | ||||

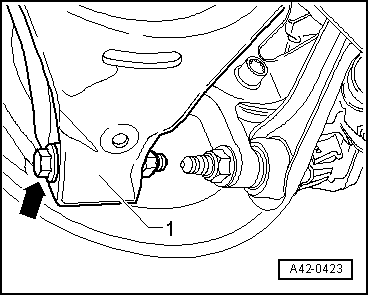

Lower transverse link to wheel bearing housing

| 90 Nm + 90° | ||||

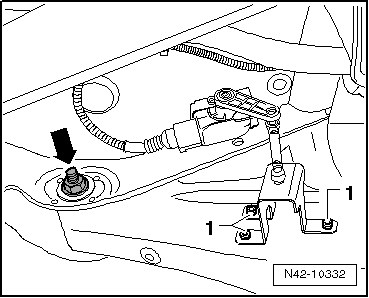

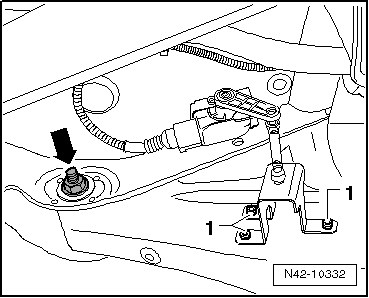

Lower transverse link to subframe

| 95 Nm |