| Component | Specified torque |

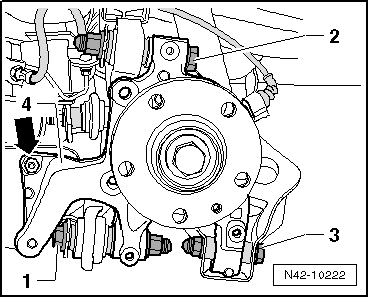

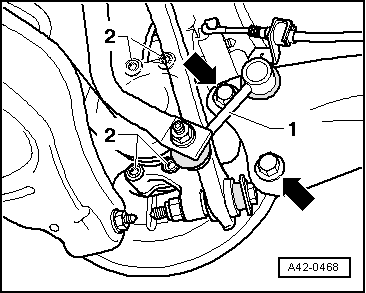

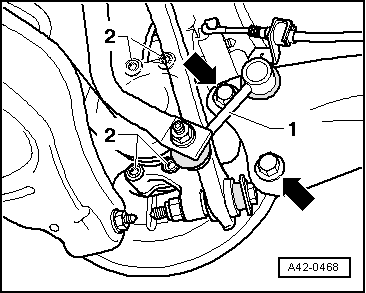

Upper transverse link to wheel bearing housing| t

| Tighten threaded connections only when vehicle is in the normal running position |

| 130 Nm + 90° further |

Wheel bearing housing to lower suspension link| t

| Tighten threaded connections only when vehicle is in the normal running position |

| 90 Nm + 90° further |

Wheel bearing housing to track rod| t

| Tighten threaded connections only when vehicle is in the normal running position |

| 130 Nm + 90° further |

| Trailing arm to wheel bearing housing | 90 Nm + 45° further |

| Coupling rod to wheel bearing housing. | 45 Nm |

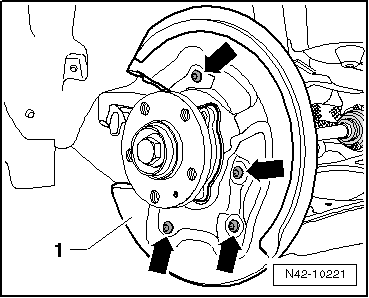

| Splash plate to wheel bearing housing | 12 Nm |

| ABS speed sensor to wheel bearing housing | 8 Nm |

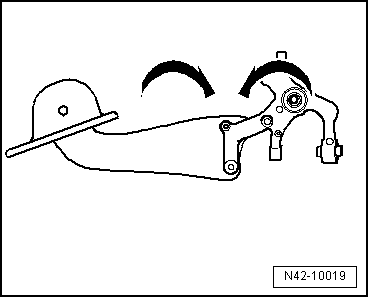

| Shock absorber to wheel bearing housing | 180 Nm |

| Brake disc to wheel bearing housing. | 4 Nm |

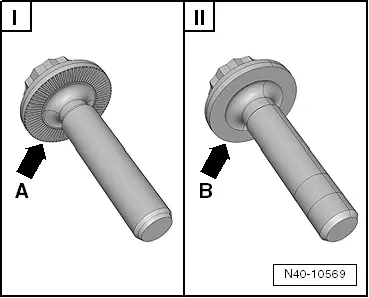

| Drive shaft to wheel hub „hexagon bolt“ | 180 Nm + 180° further |

| Drive shaft to wheel hub „twelve-point head bolt with ribbing“ | 70 Nm + 90° |

| Drive shaft to wheel hub „twelve-point head bolt without ribbing“ | 200 Nm + 180° |

Note

Note

Caution

Caution