| –

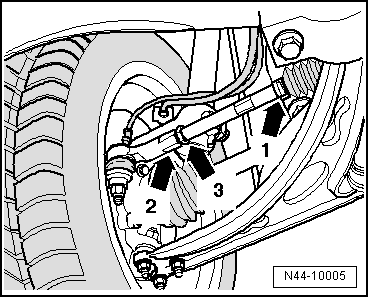

| Mark position of nut -3- on steering rack. |

| –

| Loosen nut -3- while counterholding on head of track rod -2-. |

| –

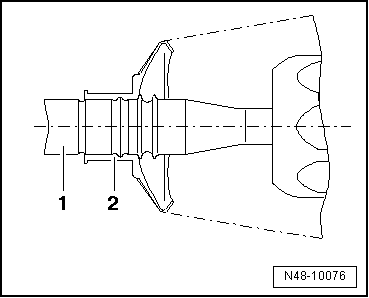

| Loosen spring-type clip -1- from boot using hose clip pliers -V.A.G 1275- and push onto track rod. |

| –

| Remove clamp and pull boot from steering box housing. |

| –

| Now turn track rod out of track rod ball joint. |

| –

| Pull boot with spring-type clip off track rod. |

Note | t

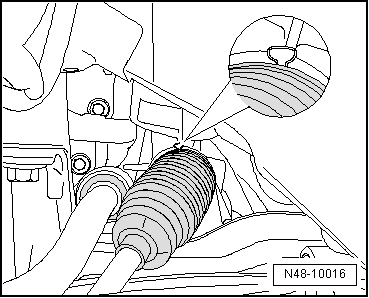

| If the steering rack shows signs of corrosion, damage, wear or soiling, renew the complete steering box. |

| t

| Likewise, if there is no film of grease on the steering rack, the steering box must be renewed. |

Caution | Do not grease steering rack. |

|

| –

| Turn steering wheel to straight-ahead position. |

| –

| Thread new clamps and rubber boot onto track rod. |

| –

| Screw in track rod to mark made during removal. |

|

|

|

Note

Note Note

Note

Caution

Caution