| –

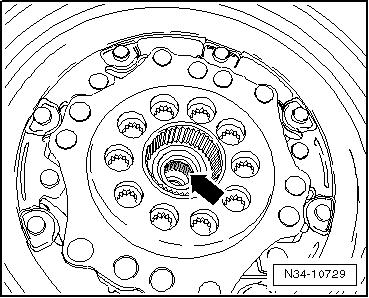

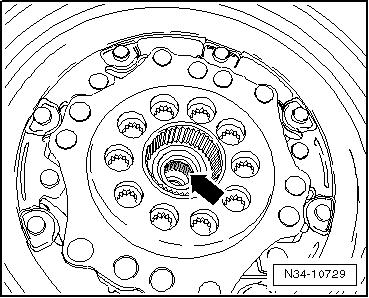

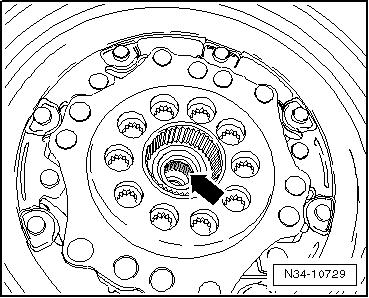

| Check needle bearing in crankshaft. If it is damaged or tarnished blue, it must be renewed → Rep. gr.13. |

| –

| If it is not damaged, grease lightly with high-temperature grease -G 052 133 A2-. |

| –

| End of gearbox shaft (but not splines) also must be lightly greased. |

| –

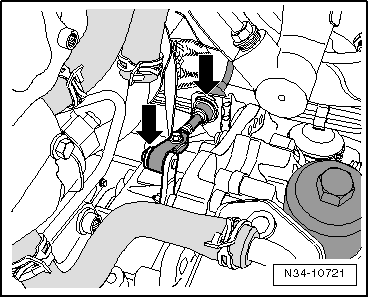

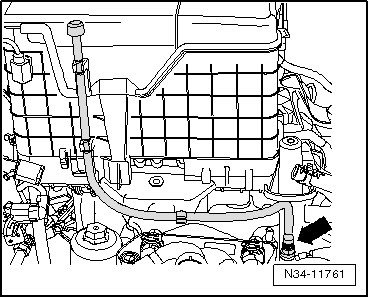

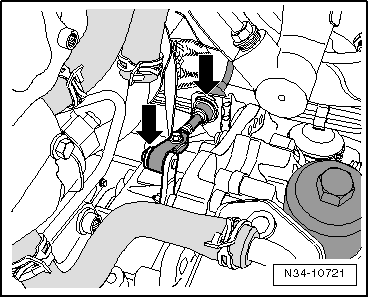

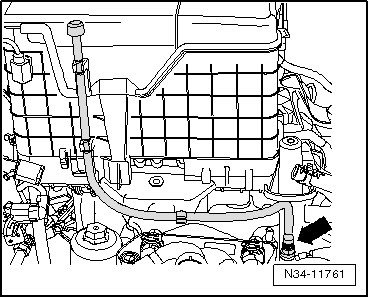

| Check for proper seating of both dowel sleeves between engine and gearbox. |

| –

| Check for proper seating of intermediate plate. |

|

|

|