Golf Mk6

|

|

|

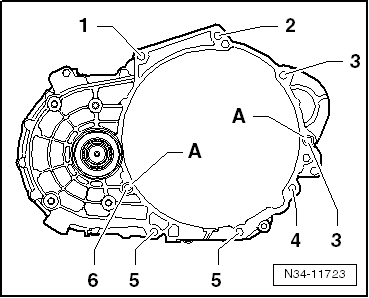

| Item | Bolt | Quantity | Nm | ||||

| 1 | M12 x 55

| 1 | 80 | ||||

| 2 | M12 x 55

M12 x 50

| 1 | 80 | ||||

| 3 | M12 x 165

| 2 | 80 | ||||

| 4 | M10 x 105 | 1 | 40 | ||||

| 5 | M10 x 50 | 2 | 40 | ||||

| 6 | M12 x 70 or M12 x 65 | 1 | 80 | ||||

| - | M6 x 8

| 1 | 10 |

|

|

|

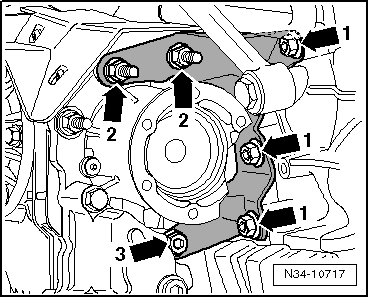

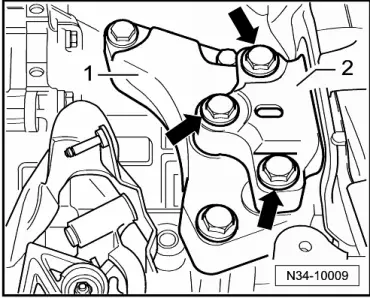

| Item | Bolt | Quantity |

| 1 | M10 x 21 | 3 |

| 2 | M10 x 45 | 2 |

| 3 | M10 x 62 | 1 |

|

|

|

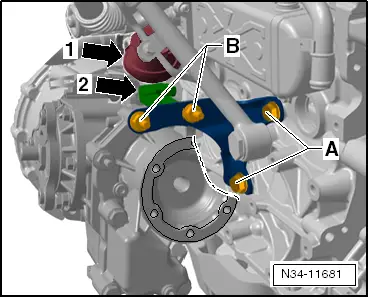

| Item | Bolt | Quantity |

| A | M10 x 21 | 2 |

| B | M10 x 45 | 2 |

|

|

|

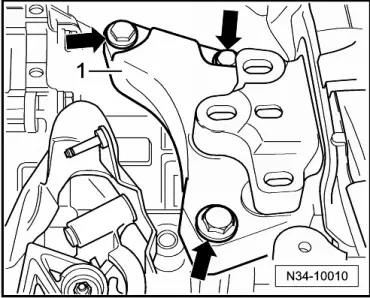

Note

Note

|

|