| –

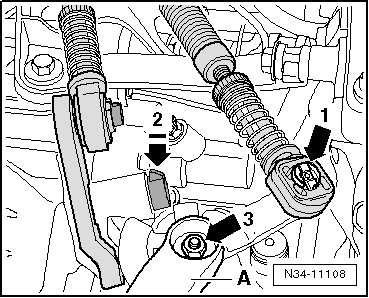

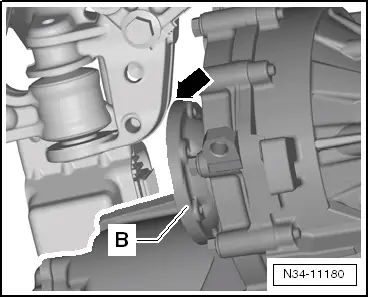

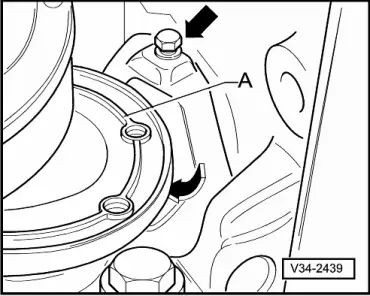

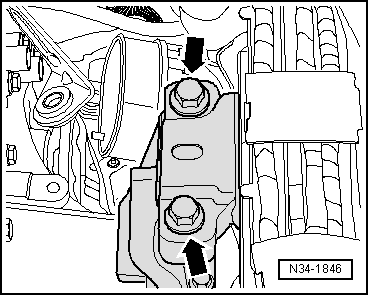

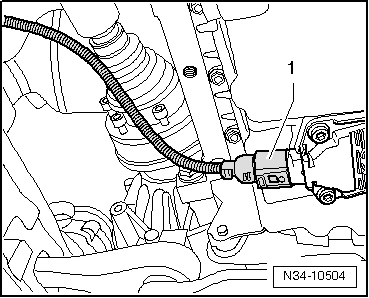

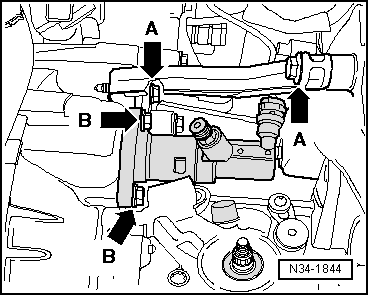

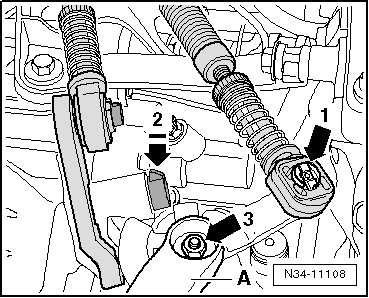

| Install gearbox selector lever -A- → Fig.. |

| –

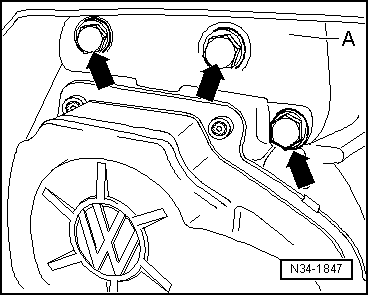

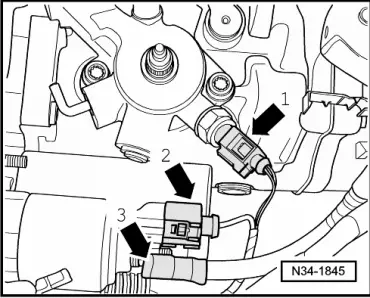

| Tighten hexagon nut -arrow 3- to specified torque → Item. |

| –

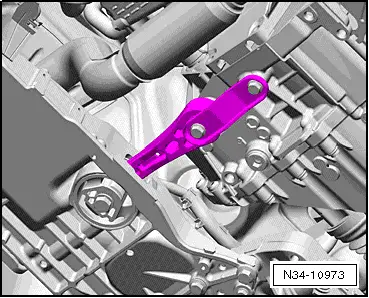

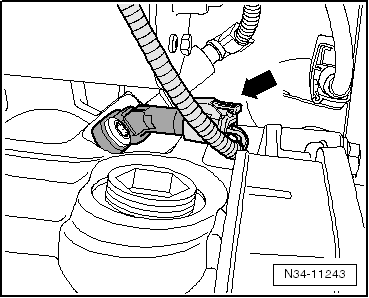

| Spread a small amount of grease on pin of gearbox selector lever -A-. |

| –

| Connect gear selector cable to gearbox selector lever. |

| –

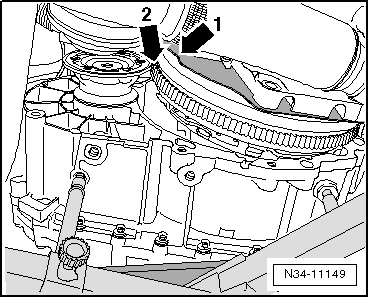

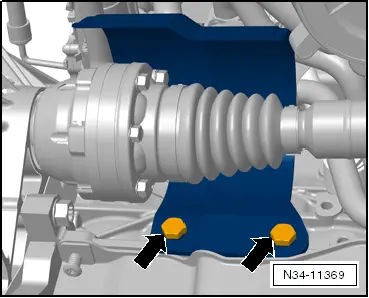

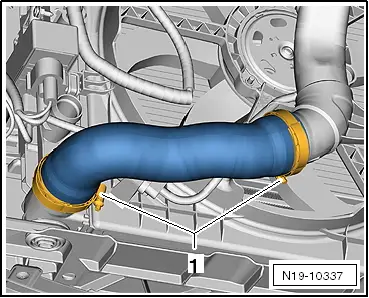

| Renew securing clip -1- each time it is removed. |

| –

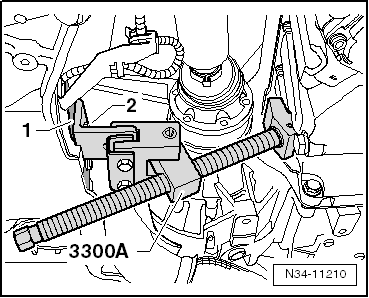

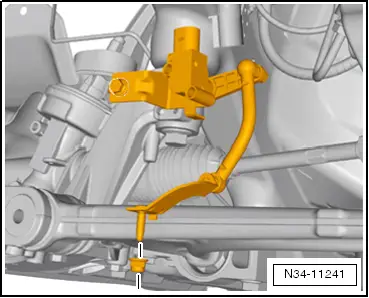

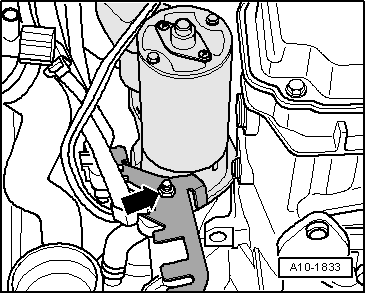

| Insert relay lever together with cable end-piece. |

| l

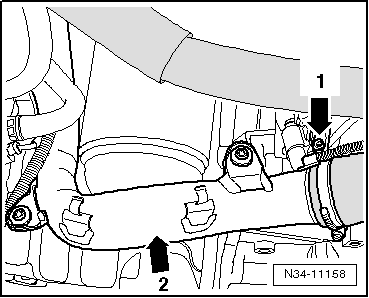

| Catch -arrow 2- secures relay lever. |

| l

| Ensure proper engagement. |

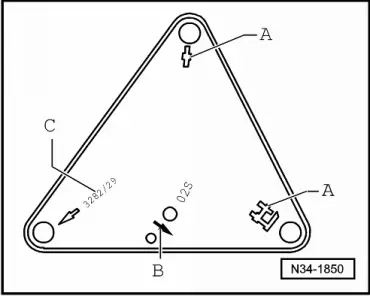

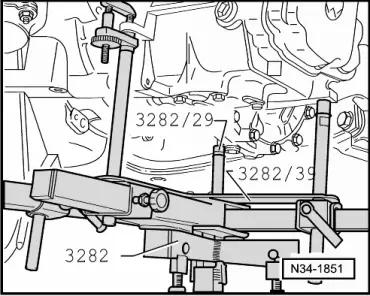

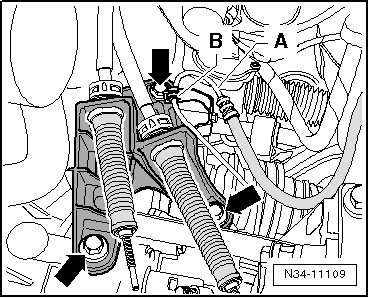

| The relay lever was secured with a clip shortly after start of production → Fig.. |

| Ensure proper engagement of clip. |

| –

| Connect gate selector cable to cable end-piece. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

WARNING

WARNING