| t

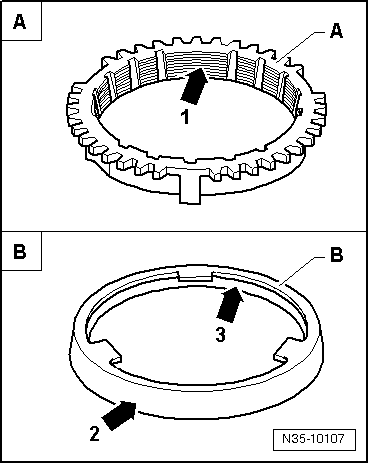

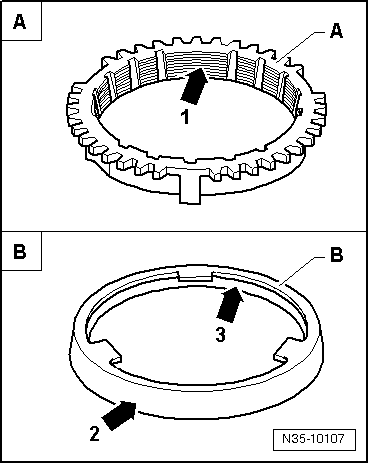

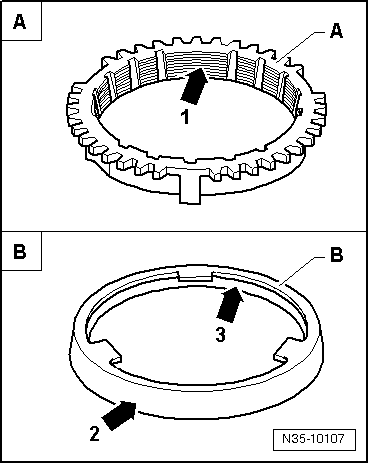

| Check grooves -arrow 1- of synchro-ring -A- and inner ring for flat spots (worn grooves). |

| t

| If synchro-rings are coated, coating must not be damaged. |

| t

| If an intermediate ring -B- is installed, check the outer friction surface -arrow 2- and inner friction surface -arrow 3- of this intermediate ring for »scoring«, »signs of abnormal wear« and »blue discolouration (due to overheating)«. |

| t

| Check cone of synchromeshed gear for »scoring« and »signs of abnormal wear«. |

| t

| Moisten synchromesh mechanism with gear oil before installing. |

| t

| Before installing, clean and heat with the inductive heater -VAS 6414- to maximum 100° C. |

| t

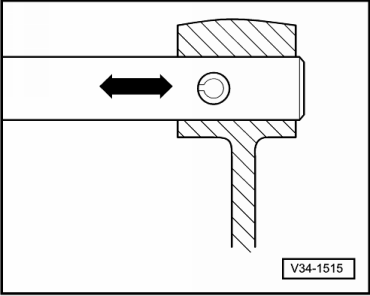

| After assembly, check synchromeshed gears for slight play, or for freedom of movement. |

| t

| Ensure that the pressure plate does not cant: loosen and tighten bolts diagonally and in several gradual stages. |

| t

| If the clutch has burnt out, thoroughly clean the clutch housing as well as the friction surface of flywheel with a cloth to reduce the smell of burnt linings. |

|

|

|