Note | If a further tightening angle is specified for certain bolts, these must be renewed. |

Caution | Risk of damage to clutch and other components! |

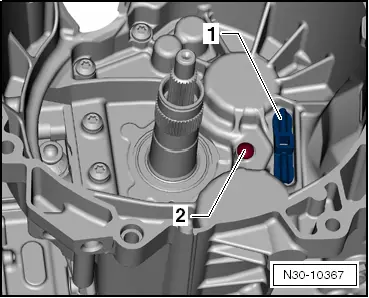

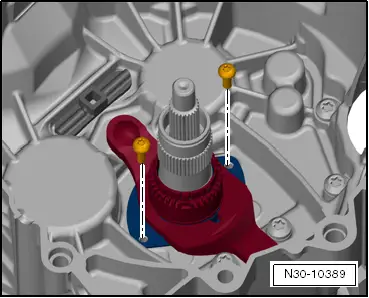

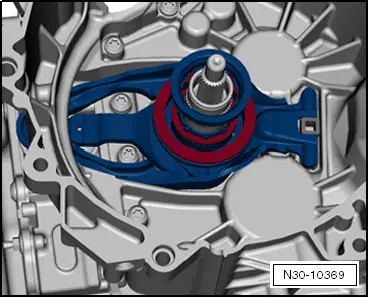

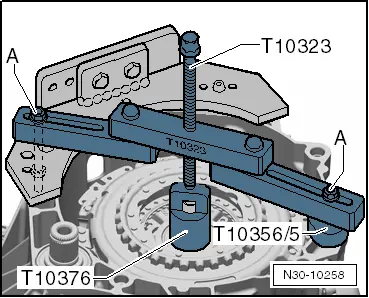

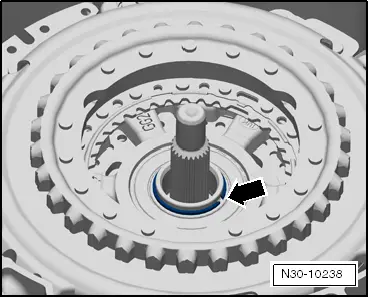

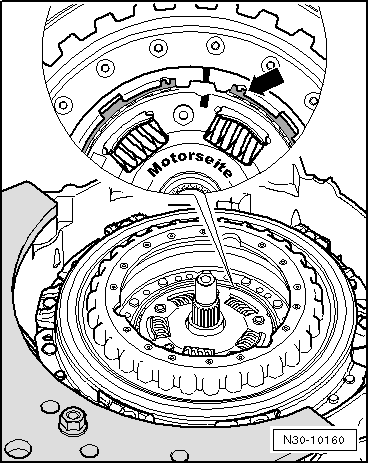

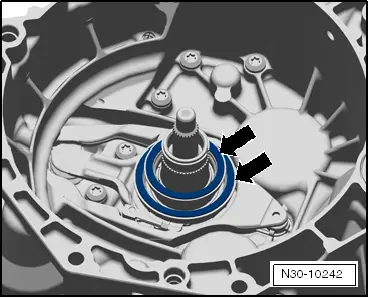

| The positions of the engagement bearings must be set correctly. |

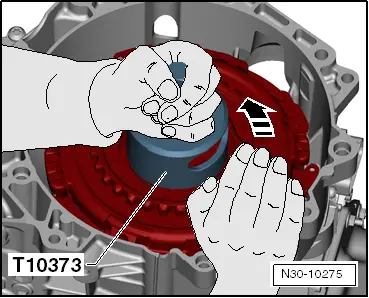

| Adjustment can only be carried out before the clutch is installed. |

| The position of the engagement bearings must be adjusted after the following tasks: |

| t

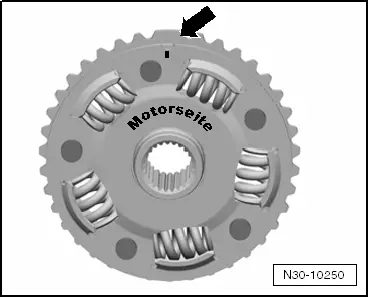

| Clutch has been renewed. |

| t

| Engaging levers were renewed. |

| t

| Retainer of engaging levers was renewed. |

| t

| Engagement bearings were renewed. |

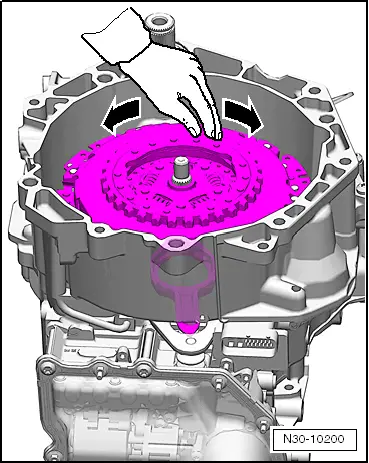

| If any of the work above has been carried out, you must now adjust the position of engagement bearings „K 1 and K 2“ → Chapter. |

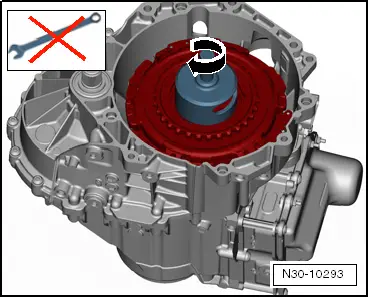

| Do not continue with assembly until the setting is correct! |

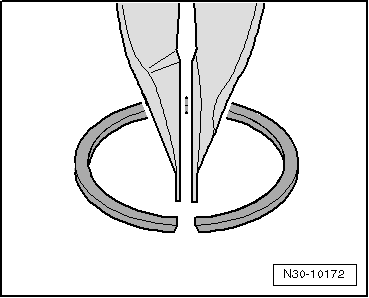

| If no new parts have been installed, use removed shims. |

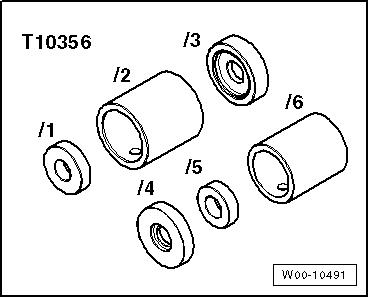

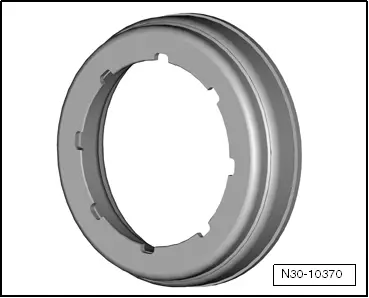

| For adjustment, only one shim per engagement bearing may be installed. |

| Clutch parts must be free of oil and grease. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING