| Installing (adjusting valve timing) |

Note | t

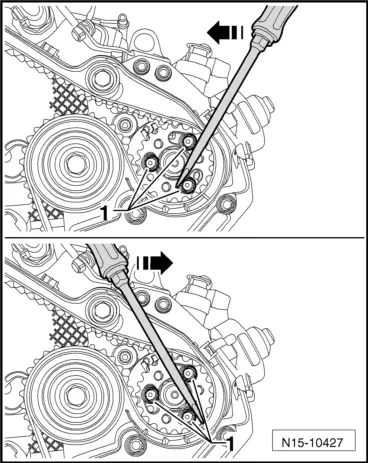

| The toothed belt may only be adjusted on cold engines, as the indicator position on the tensioning element varies depending on the engine temperature. |

| t

| If the tensioning roller is to be renewed, the engine bracket always has to be removed. |

| t

| Removing and installing engine support (Golf, Passat) → Chapter |

| t

| Removing and installing engine support (Touran) → Chapter |

| t

| Removing and installing engine support (Golf Plus) → Chapter |

| t

| Removing and installing engine support, (Polo) → Chapter |

| t

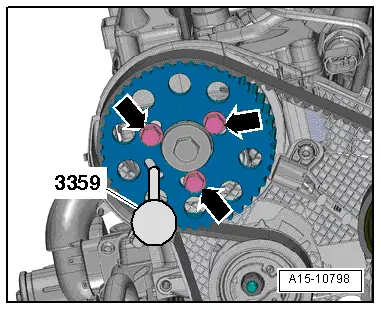

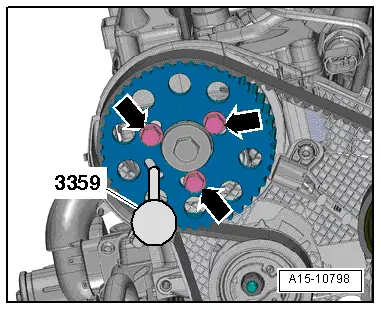

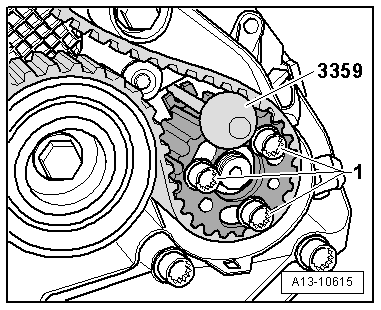

| Renew securing bolts for camshaft pulley and high-pressure pump pulley. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note