| –

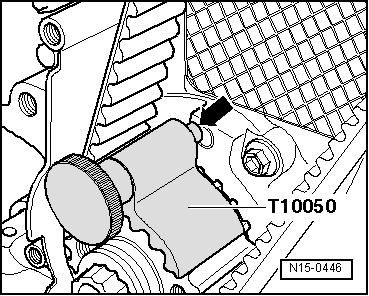

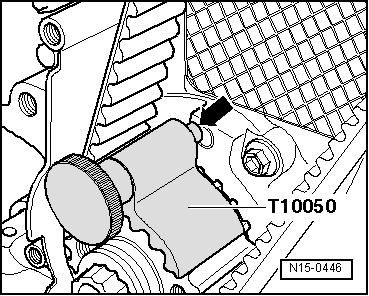

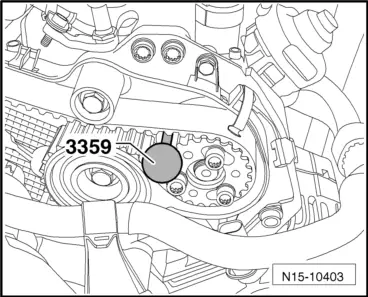

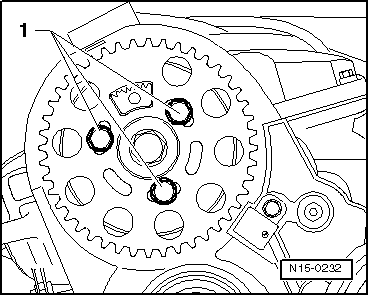

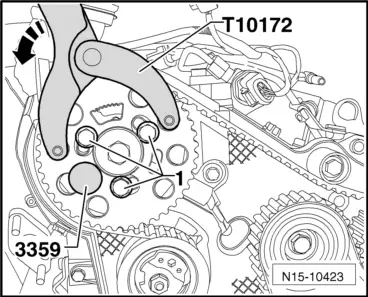

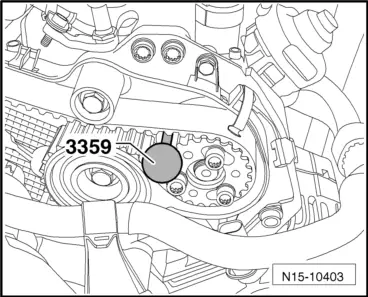

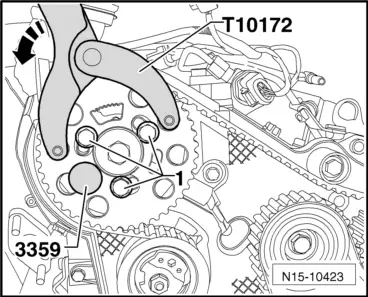

| Lock hub of high-pressure pump with locking pin -3359-. To do this, slide locking pin into adjustment hole outside toothed belt pulley. |

| –

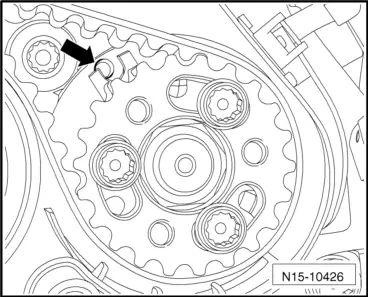

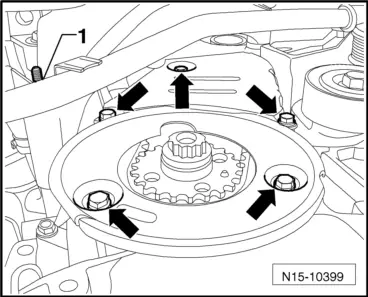

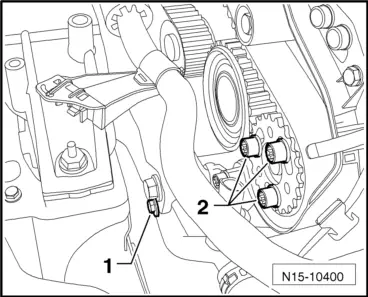

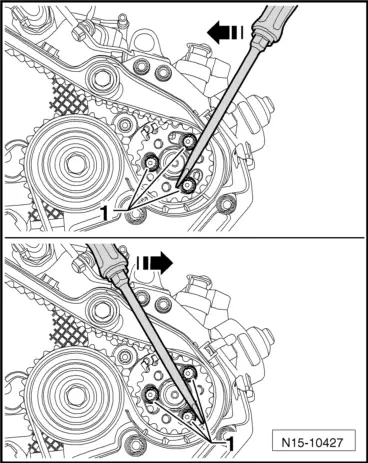

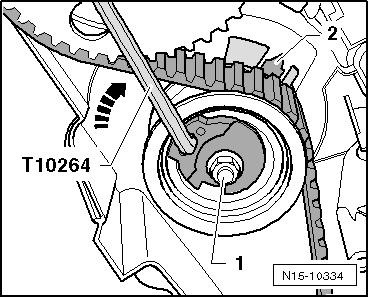

| Turn camshaft pulley and toothed belt pulley of high-pressure pump in their elongated holes clockwise to stop. |

| –

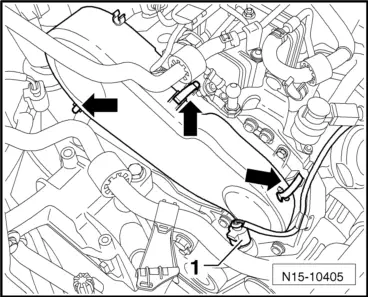

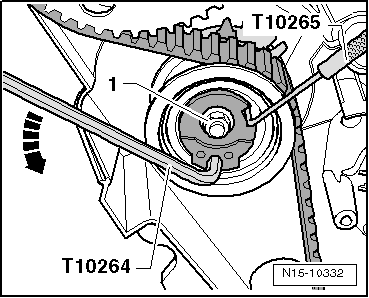

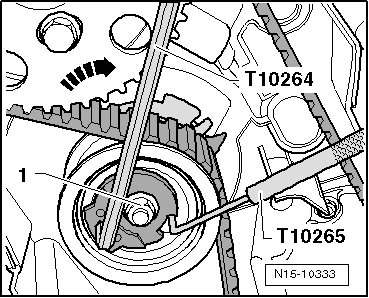

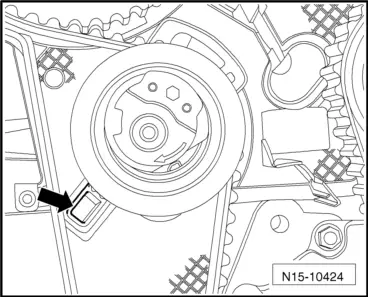

| Fit toothed belt to crankshaft toothed belt pulley, tensioning roller, camshaft pulley, toothed belt pulley of coolant pump and toothed belt pulley of high-pressure pump. |

| –

| Finally, fit toothed belt to idler roller. |

| –

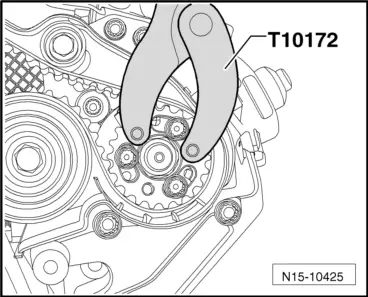

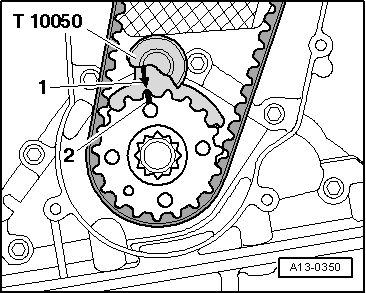

| Loosen tensioning roller securing nut and pull out locking tool -T10265-. |

Note |

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note