Golf Mk6

| Assembly overview - balancer shaft module |

Caution

Caution

|

| 1 - | Oil sump |

| q | Removing and installing → Chapter. |

| 2 - | 10 Nm |

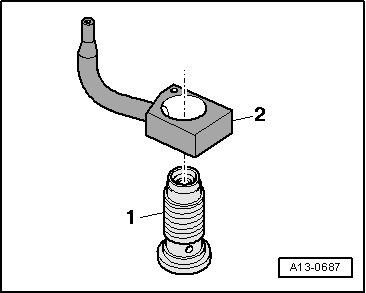

| 3 - | Intake connecting pipe |

| q | Clean strainer if soiled. |

| 4 - | 10 Nm |

| 5 - | O-ring |

| q | Renew. |

| 6 - | Oil pump |

| q | Removing and installing → Chapter. |

| q | Before installing, check that the two dowel sleeves for centring oil pump on balancer shaft module are fitted. |

| 7 - | Drive shaft for oil pump |

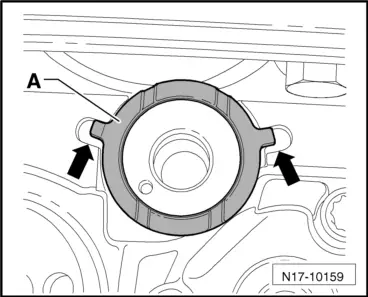

| 8 - | Circlip |

| q | Must lie in base of groove. |

| q | Renew damaged or over-tensioned circlip. |

| 9 - | Spur gear for balancer shaft |

| 10 - | 20 Nm + turn 90° further |

| q | Renew. |

| 11 - | Hub |

| q | For intermediate gear wheel. |

| q | Renew. |

| 12 - | 90 Nm + turn 90° further |

| q | Renew. |

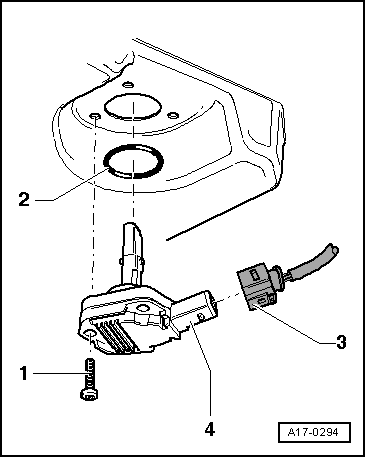

| 13 - | Thrust washer |

| q | For intermediate gear wheel. |

| q | Renew. |

| q | Note installation position → Fig.. |

| 14 - | Intermediate gear wheel |

| q | Renew. |

| q | A coating is applied to the new intermediate gear wheel which sets the correct tooth backlash through wear. |

Caution

Caution

|

| q | Installation position: Part number must be visible. |

| q | Installing → Chapter. |

| 15 - | Thrust washer |

| q | For intermediate gear wheel. |

| q | Renew. |

| q | Note installation position → Fig.. |

| q | If necessary, attach to housing with grease when installing intermediate gear wheel |

| 16 - | Spur gear for crankshaft |

| q | Renew if signs of wear are found → Chapter |

| 17 - | Balancer shaft module |

| q | Removing → Chapter |

| q | Installing new balancer shaft module → Chapter. |

| q | Reinstalling previously run balancer shaft module → Chapter. |

| q | Before installing, check that the two dowel sleeves for centring balancer shaft module on cylinder block are fitted. |

| 18 - | M7 = 13 Nm + 90° further; M8 = 20 Nm + 90° further |

| q | Renew. |

| q | Note tightening sequence: installing new balancer shaft module → Chapter, reinstalling previously run balancer shaft module → Chapter. |

| 19 - | Oil extraction pipe |

| 20 - | 10 Nm |

| 21 - | 40 Nm |

| 22 - | 45 Nm |

| 23 - | 15 Nm |

| q | Tighten in stages and in diagonal sequence. |

| 24 - | Seal |

| q | Permanently attached to drain plug |

| 25 - | Oil drain plug, 30 Nm |

| q | With seal. |

| q | Renew. |

|

|

|

|