Golf Mk6

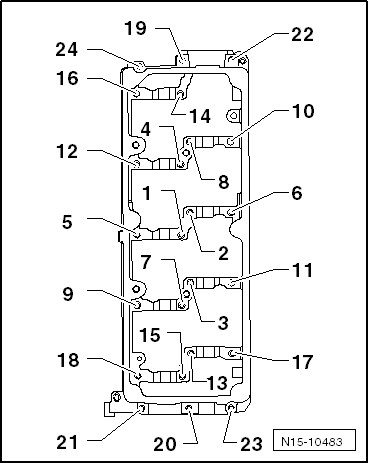

| Assembly overview - valve gear |

Caution

Caution

|

Note

Note| Cylinder heads with cracks between the valve seats may continue to be used without reducing engine life, provided the cracks are small and not more than 0.5 mm wide. |

| 1 - | Valve |

| q | Do not rework. Only lapping in is permitted. |

| q | Mark installation position for re-installation. |

| q | Checking → Chapter. |

| q | Valve dimensions → Chapter. |

| q | Checking valve guides → Chapter. |

| 2 - | Cylinder head |

| 3 - | Valve stem seal |

| q | Renewing with cylinder head installed → Chapter. |

| q | Renewing with cylinder head removed → Chapter. |

| 4 - | Valve spring |

| 5 - | Valve spring plate |

| 6 - | Valve cotters |

| 7 - | Cap |

| q | Renew. |

| q | Removing: With retaining frame installed, pierce one side of cap with an awl and pry out. |

| q | Installing: Drive in without sealant using an appropriate thrust piece. |

| q | Insertion depth 1 … 2 mm. |

| 8 - | Oil seal |

| q | Renewing → Chapter. |

| 9 - | Exhaust camshaft |

| q | Removing and installing → Chapter. |

| q | Measuring axial clearance → Chapter. |

| q | Measuring radial clearance → Chapter |

| 10 - | Bolt |

| q | Specified torque and tightening sequence → Fig.. |

| 11 - | Retaining frame |

| q | With integrated camshaft bearings. |

| q | Specified torque and tightening sequence → Fig.. |

| 12 - | Inlet camshaft |

| q | Removing and installing → Chapter. |

| q | Measuring axial clearance → Chapter. |

| q | Measuring radial clearance → Chapter |

| 13 - | Roller rocker finger |

| q | Mark installation position for re-installation. |

| q | Check roller bearing for ease of movement. |

| q | Lubricate contact surfaces before installing. |

| 14 - | Securing clip |

| q | For hydraulic compensation element. |

| 15 - | Hydraulic compensation element |

| q | Mark installation position for re-installation. |

| q | Lubricate contact surfaces before installing. |

|

|

| Stage | Bolts | Specified torque | ||

| 1. | -1 … 24- | Screw in to contact by hand

| ||

| 2. | -1 … 24- | 10 Nm |