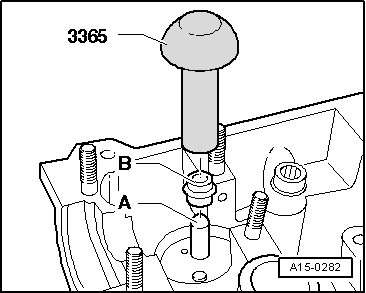

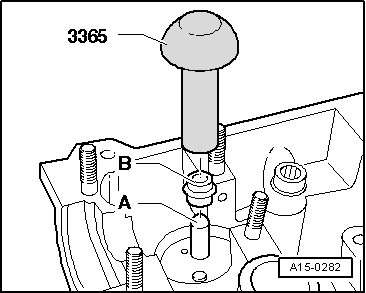

Caution | Risk of damage when installing valve stem seals. |

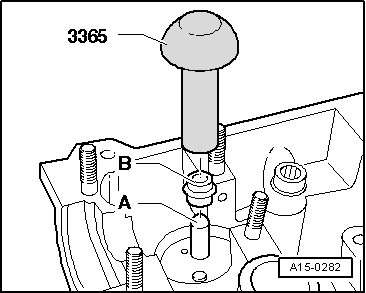

| Place plastic sleeve -A-, enclosed with new valve stem seals -B-, onto valve stem. |

|

| –

| Lightly oil sealing lip of valve stem seal. |

| –

| Push valve stem oil seal onto plastic sleeve. |

| –

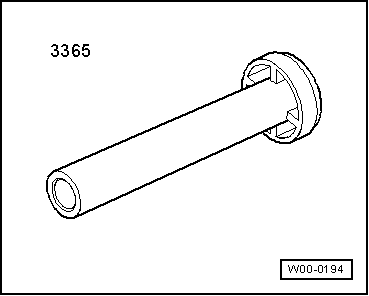

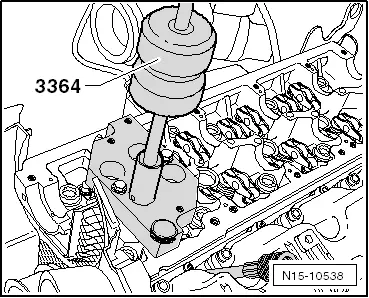

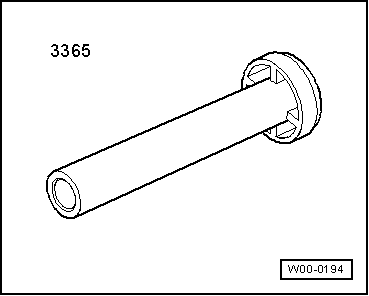

| Carefully press valve stem oil seal onto valve guide using valve stem seal fitting tool -3365-. |

|

|

|