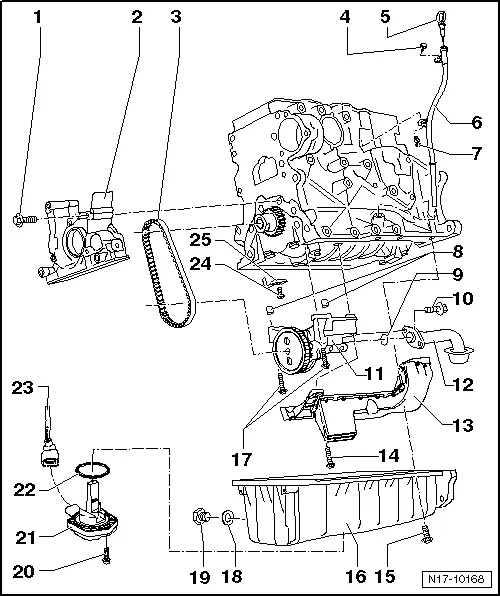

Golf Mk6

| Assembly overview - oil pump/sump, engine codes CFHB, CFHC, CFJA, CLCA |

| 1 - | 15 Nm |

| 2 - | Sealing flange |

| q | With seal. |

| q | Must seat on dowel sleeves. |

| q | Removing and installing → Chapter. |

| q | Install with silicone sealant -D 176 404 A2-. |

| q | Do not additionally oil or grease the oil seal sealing lip. |

| q | Before installing, remove oil residue from crankshaft journal using a clean cloth. |

| q | Renewing crankshaft oil seal, belt pulley end → Chapter. |

| 3 - | Toothed belt for oil pump |

| q | Check for damage and wear. |

| q | Renew if necessary. |

Note

Note| t | Belts which have been in use longer can sag. |

| t | This is not a fault and does not necessarily mean belt needs replacing. |

| 4 - | 10 Nm |

| 5 - | Oil dipstick |

| q | The oil level must not be above the max. mark! |

| q | Markings → Chapter. |

| 6 - | Guide tube |

| 7 - | Clip |

| 8 - | Dowel sleeves |

| q | Renew. |

| 9 - | O-ring |

| q | Renew. |

| 10 - | 10 Nm |

| 11 - | Oil pump with pressed-on toothed belt pulley |

| q | With 12 bar pressure relief valve |

| q | Before installing, check that both dowel sleeves for centring oil pump on cylinder block are fitted. |

| If toothed belt or oil pump have to be removed: |

| t | Check oil pump for free movement. |

| t | It should be possible to turn belt pulley easily with 1 finger. |

| t | Renew if tight/sticking. |

| 12 - | Suction line |

| q | Clean strainer if soiled. |

| 13 - | Baffle plate |

| 14 - | 15 Nm |

| 15 - | Bolt |

| q | Specified torques and installation sequence → Chapter. |

| 16 - | Oil sump |

| q | Clean sealing surface before fitting. |

| q | Install with silicone sealant -D176404A2-. |

| q | Removing and installing → Chapter |

| 17 - | 15 Nm |

| 18 - | Seal |

| q | Renew. |

| 19 - | Oil drain plug, 30 Nm |

| q | Renew. |

| 20 - | 10 Nm |

| 21 - | Oil level and oil temperature sender -G266- |

| q | Black 3-pin connector |

| q | Removing and installing → Chapter |

| 22 - | Seal |

| q | Renew. |

| 23 - | Oil level/oil temperature sender wiring harness |

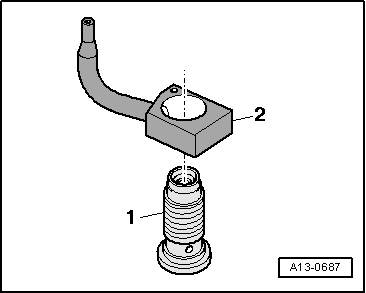

| 24 - | 27 Nm |

| q | Insert without sealant. |

| 25 - | Oil spray jet |

Note

Note

|

|