| –

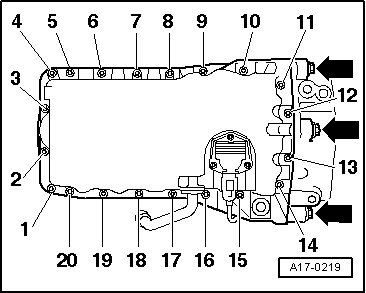

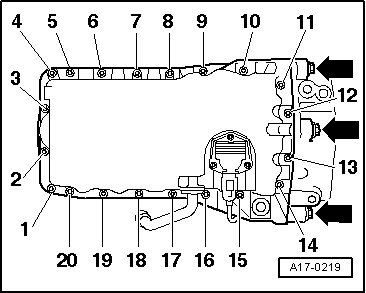

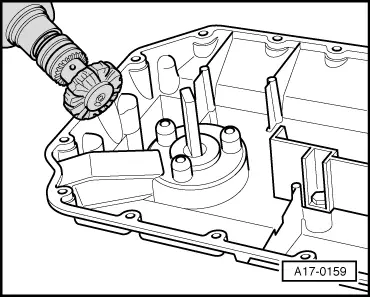

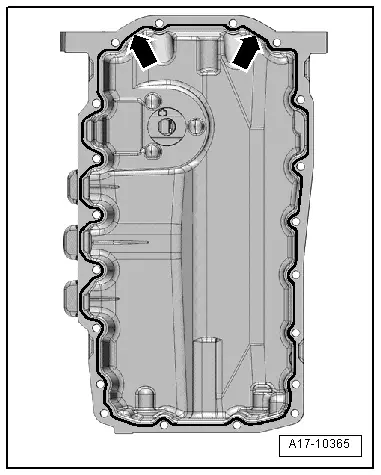

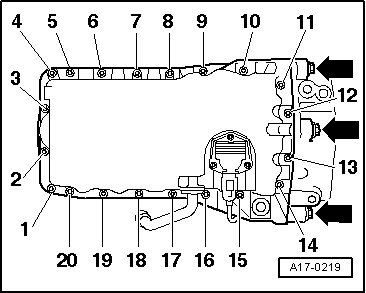

| Position oil sump and tighten bolts → Fig.. |

| l

| The oil sump must be flush with the gearbox flange at the intermediate plate. |

Note | t

| When installing sump with engine removed from the vehicle, ensure that sump is flush with cylinder block at flywheel end. |

| t

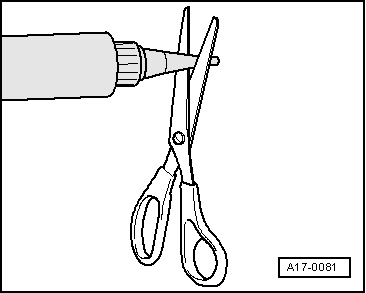

| Allow sealant to dry for approx. 30 minutes after installing sump. Only then fill with engine oil. |

| –

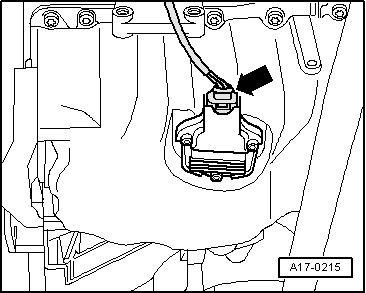

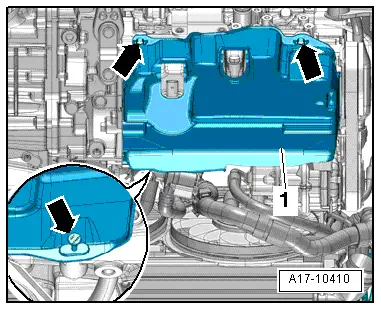

| Install coolant circulation pump 2 -V178-. |

| –

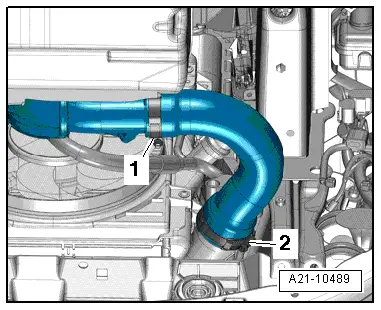

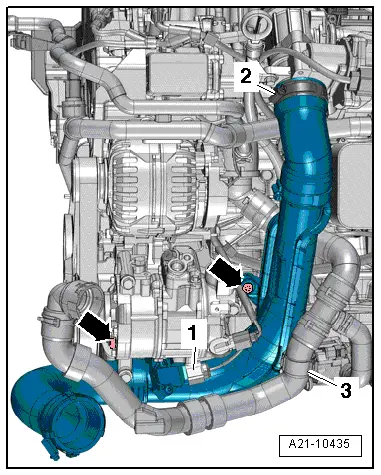

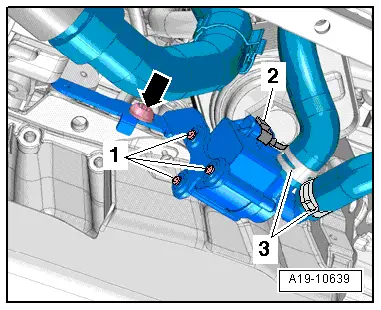

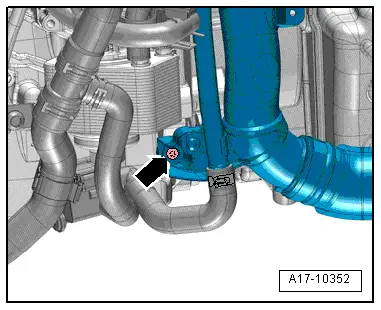

| Installing intake hoses with screw-type clips → Fig.. |

| –

| Replenish engine oil and check oil level → Booklet. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING