Caution | If a mechanical fault is discovered on the turbocharger (e.g. a destroyed compressor impeller), it is not sufficient to just renew the turbocharger. To avoid any subsequent damage, the following work must be carried out: |

| t

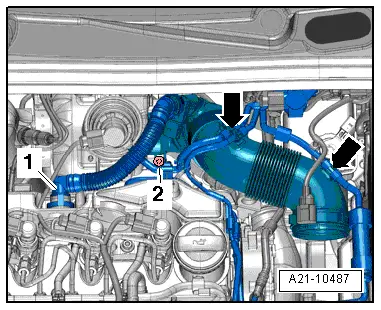

| Check air filter housing, air filter element and air inlet hoses for contamination. |

| t

| Check the whole charge air path and charge air cooler for foreign objects. |

| t

| If foreign objects are discovered in the charge air system, clean the charge air path and, if necessary, renew the charge air cooler. |

|

Note

Note

Note

Note

Note

Note

Note

Note