| –

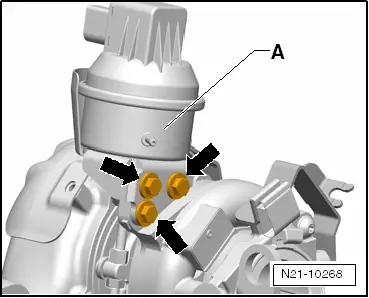

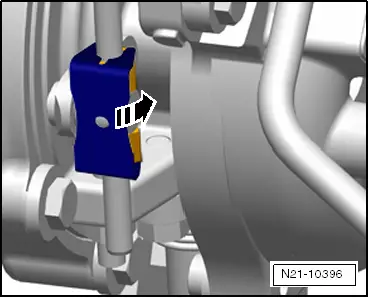

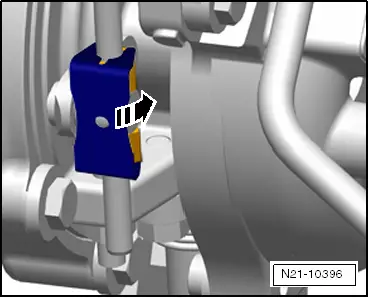

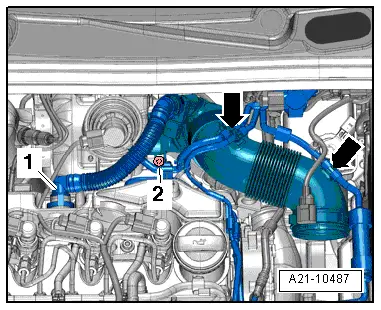

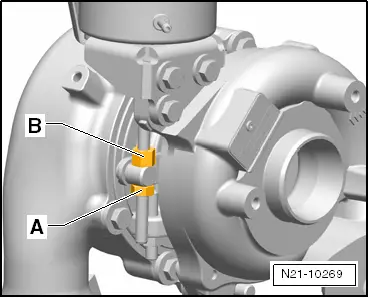

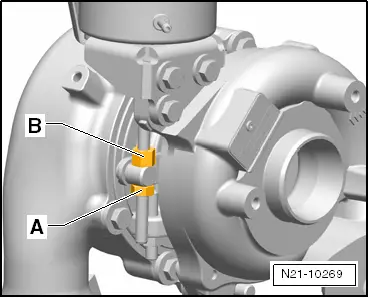

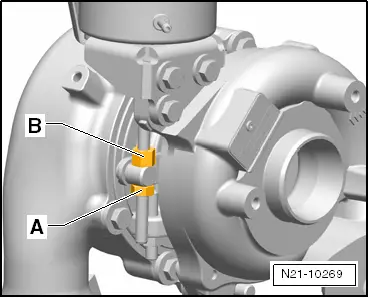

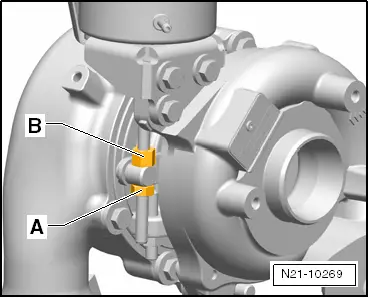

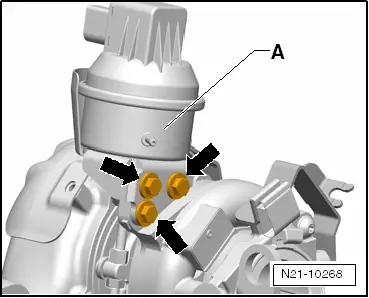

| Press locking plate by hand onto the control rod and, if possible, turn 90° in the -direction of the arrow-. |

| –

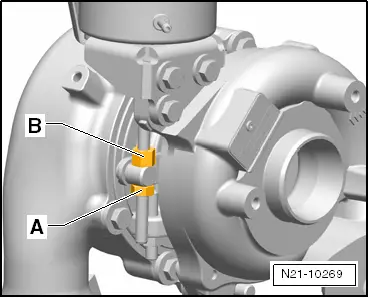

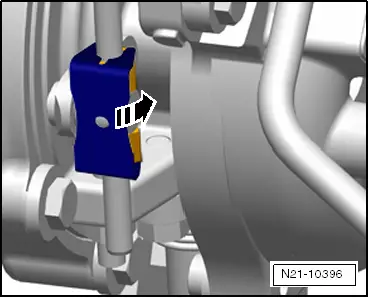

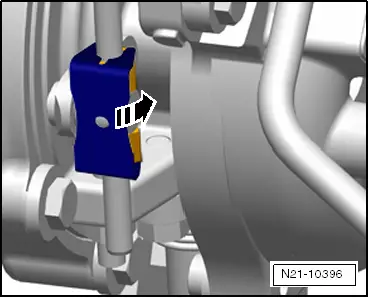

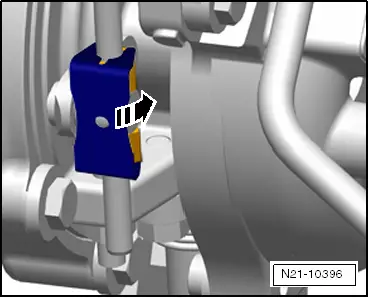

| Seal connection between control rod and securing nut with sealing paint from the spare-parts kit. |

| –

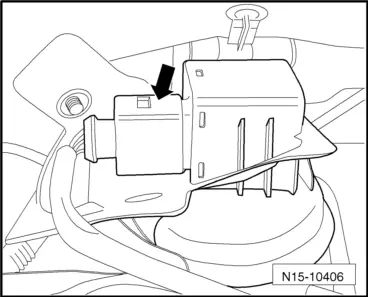

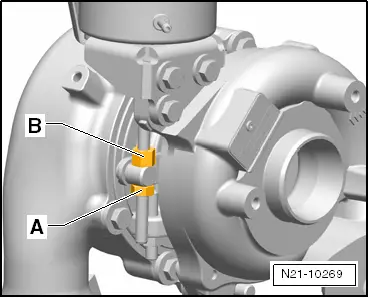

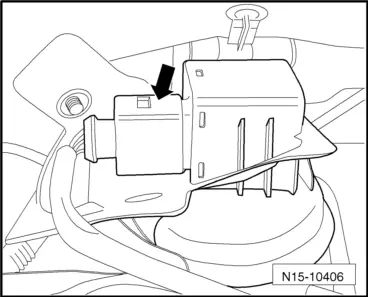

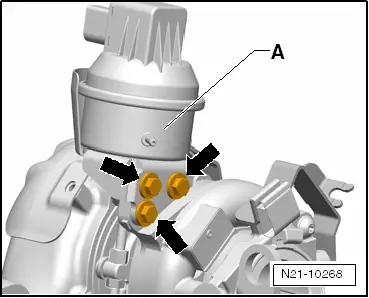

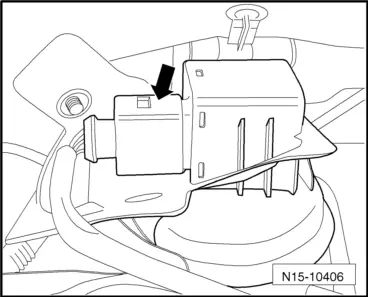

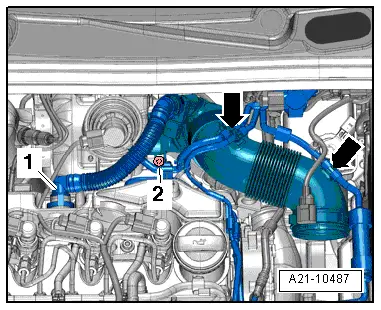

| Remove sealing cap from turbocharger. |

| –

| Check setting as follows: |

| Select diagnostic function: |

| –

| Click the „006 - Basic setting“ button on the display. |

| –

| Select „Adaption of turbocharger“ from selection list. |

| –

| Click the „Measured values“ button on the bottom right on the display. |

| –

| Select „Positioner for high pressure turbocharger, actual raw voltage“ from selection list. |

| –

| Click the „Start“ button on the bottom right on the display. |

| –

| Observe the value in the lower screen window; it must fluctuate between 650 ... 850 mV and 3,000 ... 3,400 mV (vacuum unit is move to both end stops alternately). |

| –

| End basic setting procedure. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note