Golf Mk6

| Assembly overview |

| 1 - | 40 Nm + 1/4 turn (90°) further |

| q | Left-hand thread. |

| q | Renew. |

| 2 - | Camshaft adjuster |

| q | Must not be dismantled. |

| q | Removing and installing → Chapter. |

| 3 - | Camshaft pulley |

| q | Note position when installing timing chain. |

| 4 - | O-ring |

| q | Renew if damaged. |

| q | Before installing, coat lightly with engine oil. |

| 5 - | Inlet camshaft control valve 1 -N205- |

| 6 - | 10 Nm |

| 7 - | 10 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Tighten from inside outwards. |

| 8 - | Camshaft housing |

Caution

Caution

|

| q | Removing and installing → Chapter |

| q | Remove sealant residue. |

| q | Coat with D 154 103 A1 before fitting. |

| q | When installing, fit vertically from above onto studs and dowel pins. |

| 9 - | 10 Nm |

| 10 - | Cap |

| q | For inlet camshaft. |

| q | For exhaust camshaft. |

| 11 - | Roller rocker finger |

| q | Check roller bearing. |

| q | Oil contact surface. |

| q | When installing, secure to supporting element using securing clip. |

| 12 - | Valve cotters |

| 13 - | Valve stem seal |

| q | Renew. |

| 14 - | Support element |

| q | Check oil spray holes. |

| q | With hydraulic valve clearance compensation. |

| q | Do not interchange. |

| q | Before installing, check camshaft axial clearance → Chapter. |

| q | Oil contact surface. |

| 15 - | Valve guide |

| q | Checking → Chapter. |

| 16 - | Valve spring |

| q | To remove and install with cylinder head removed, use valve spring tool -3362-. |

| q | With cylinder head installed → Chapter. |

| 17 - | Cylinder head |

| q | Removing and installing → Chapter |

| q | Reworking valve seat → Chapter. |

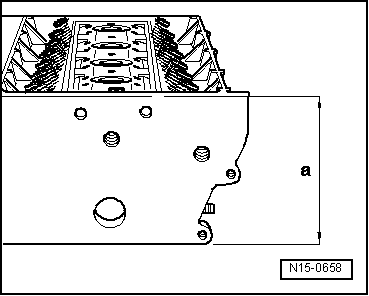

| q | Reworking sealing surface → Fig.. |

| 18 - | Valves |

| q | Do not rework, only lapping-in is permitted. |

| q | Valve dimensions → Fig. |

| 19 - | Exhaust camshaft |

| q | Do not interchange with inlet camshaft. |

| q | Checking axial clearance → Chapter. |

| q | Coat with oil before inserting (also axial bearing shoulder). |

| 20 - | Guide sleeve |

| 21 - | Inlet camshaft |

| q | With cam for high-pressure pump -arrow-. |

| q | Before removing, remove and renew bucket tappet for high-pressure pump. |

| q | Do not interchange with exhaust camshaft. |

| q | Checking axial clearance → Chapter. |

| q | Coat with oil before inserting (also axial bearing shoulder). |

| 22 - | 50 Nm + 1/4 turn (90°) further |

| q | Always renew after removing. |

Note

Note

|

|