| –

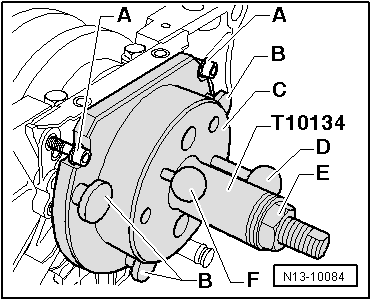

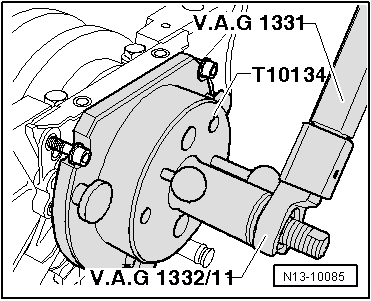

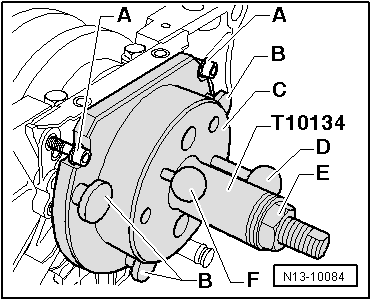

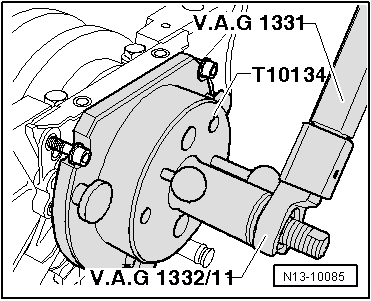

| Tighten hexagon nut of assembly tool -T10134- to 40 Nm using torque wrench -V.A.G 1331- and tool insert 24 mm -V.A.G 1332/11-. |

| –

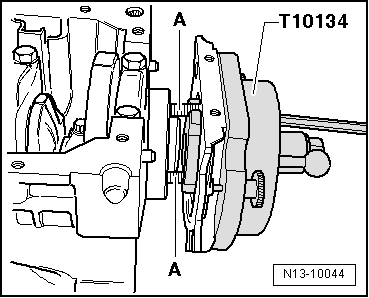

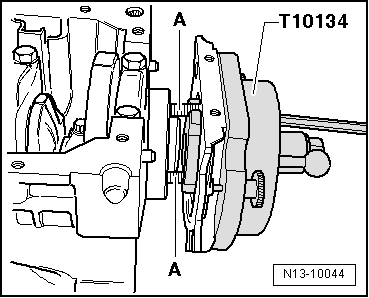

| Check installation position of sender wheel on crankshaft again → Chapter. |

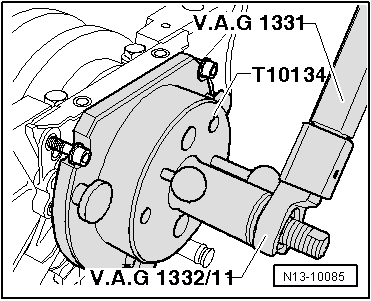

| If dimension »a« is too small again: |

| –

| Tighten hexagon nut for assembly tool -T10134- to 45 Nm. |

| –

| Check installation position of sender wheel on crankshaft again → Chapter. |

|

|

|