| –

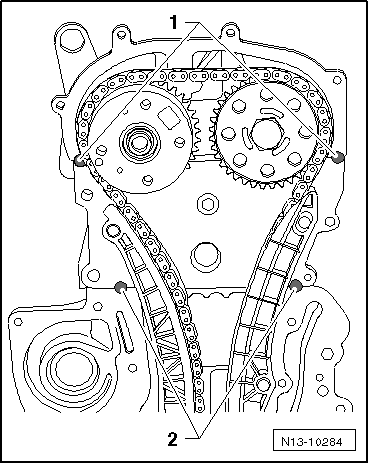

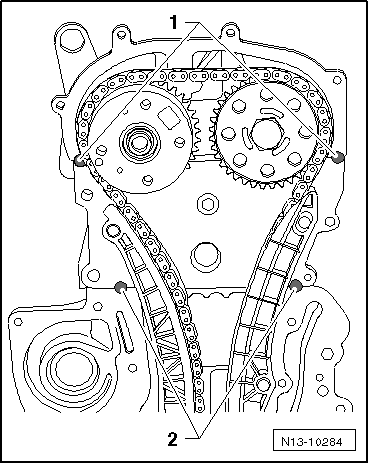

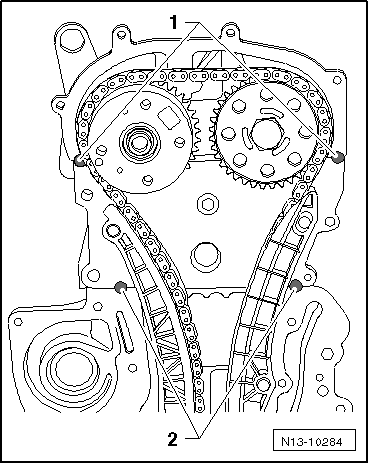

| Apply silicone adhesive sealant -D 176 501 A1- to joints between camshaft housing and cylinder head -1- and between cylinder head and cylinder block -2-. |

| –

| Fit new gasket onto dowel pins. |

| –

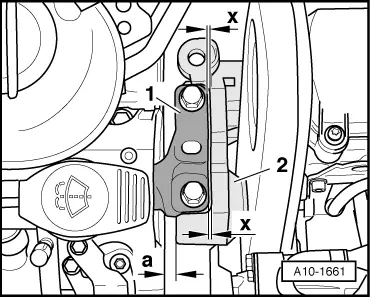

| When fitting, install two -M6x80- studs into cylinder head and cylinder block as a guide. |

| –

| Fit valve timing housing with crankshaft bearing bush simultaneously onto studs, dowel pins and crankshaft journal. |

| –

| Tighten valve timing housing securing bolts evenly and diagonally. |

| Ensure that timing housing is not canted. |

| Eos, Golf Plus, Scirocco, Golf, Golf Cabriolet, Sharan |

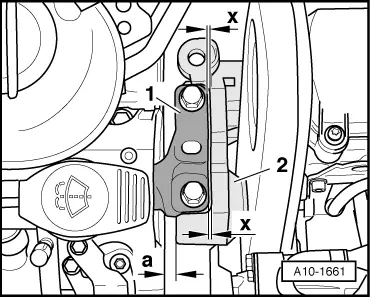

| Align engine mountings as follows: |

|

|

|

Note

Note Note

Note

Note

Note Note

Note