| –

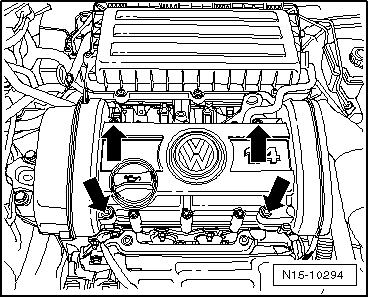

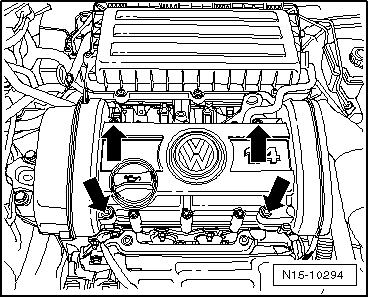

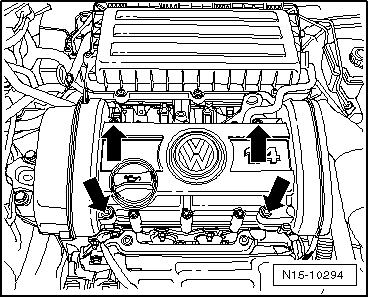

| Unscrew bolts -arrows- and remove cover from camshaft housing (engine codes BUD, CGGA). |

| –

| Remove ignition coils using puller -T10094 A- → Chapter. |

| –

| Remove spark plugs using spark plug socket 3122 B. |

| –

| Check compression using compression tester -V.A.G 1381- or -V.A.G 1763-. |

Note | How to use the test unit is described in the respective operating instructions. |

| –

| Operate starter until tester shows no further pressure increase. |

| Maximum permissible difference between all cylinders: 3 bar |

| –

| Insert spark plugs using spark plug socket and extension -3122 B- and tighten to 30 Nm. |

| Further assembly is basically the reverse of the dismantling sequence. |

| The readiness code must be generated if the fault memory has been erased. |

|

|

|

Note

Note

Note

Note