Golf Mk6

Note

Note

|

| 1 - | Circlip |

| 2 - | Piston pin |

| q | If difficult to remove, heat piston to 60 °C. |

| q | Remove and install with drift -10-14-. |

| 3 - | Piston |

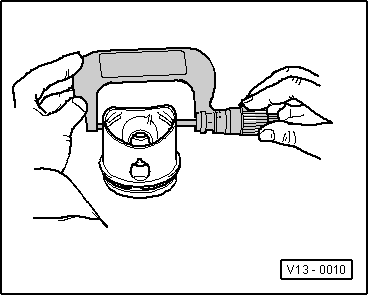

| q | Check → Fig.. |

| q | Mark installation position and cylinder number. |

| q | Arrow on piston crown points to belt pulley end. |

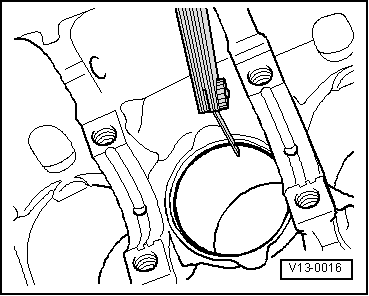

| q | Install using piston ring clamp. |

| 4 - | Compression rings |

| q | Offset gaps by 120°. |

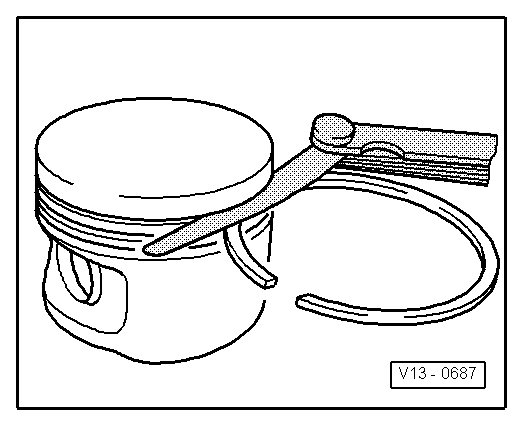

| q | Remove and install compression rings with piston ring pliers. |

| q | „TOP“ faces towards piston crown. |

| q | Checking ring gap → Fig.. |

| q | Checking ring-to-groove clearance → Fig.. |

| 5 - | Oil scraper rings |

| q | Carefully remove and install 3-part oil scraper rings by hand. |

| q | Checking ring gap → Fig.. |

| q | Ring-to-groove clearance not measurable. |

| 6 - | Conrod |

| q | Renew as set only. |

| q | Mark with cylinder number -A-. |

| q | Installation position: Marking -B- faces towards pulley end. |

| q | Guided axially by piston. |

| 7 - | Conrod bearing cap |

| q | The caps only fit in one position and only on the appropriate conrod due to the breaking procedure (cracking) separating the cap from the conrod. |

| 8 - | Conrod bolt |

| q | M7×0.75: 20 Nm + 1/4 turn (90°) further. |

| q | M8×1: 30 Nm + 1/4 turn (90°) further. |

| q | Renew. |

| q | Oil threads and contact surface. |

| q | To measure radial clearance, tighten to corresponding specified torque but not further. |

| 9 - | Cylinder block |

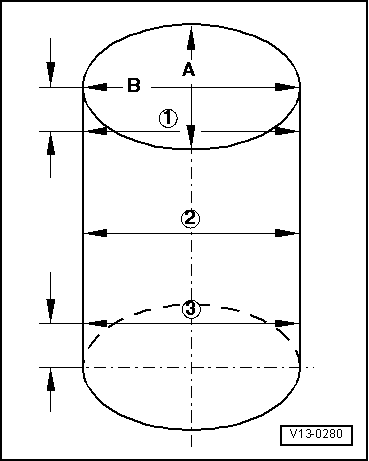

| q | Checking cylinder bores → Fig.. |

| q | Piston and cylinder dimensions → Chapter. |

| 10 - | Bearing shell |

| q | Do not interchange used bearing shells. |

| q | Insert bearing shells centrally. |

| Check radial clearance with Plastigage. |

Note

Note| Do not rotate crankshaft when checking radial clearance. |

| q | New: 0.020…0.061 mm. |

| q | Wear limit: 0.091 mm |

|

|

| Piston ring dimensions in mm | New | Wear limit |

| 1st compression ring | 0.20...0.50 | 1.0 |

| 2nd compression ring | 0.40...0.70 | 1.0 |

| Oil scraper ring | 0.40...1.40 | --- → Remark |

|

|

|

| Piston ring dimensions in mm | New | Wear limit |

| 1st compression ring | 0.04...0.08 | 0.15 |

| 2nd compression ring | 0.04...0.08 | 0.15 |

| Oil scraper ring | Not measurable | |

|

|

Note

Note

|

|