| –

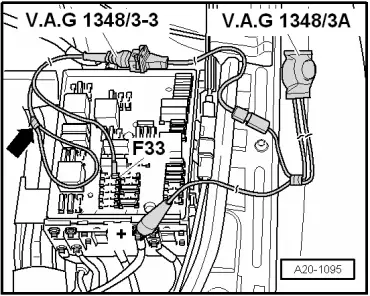

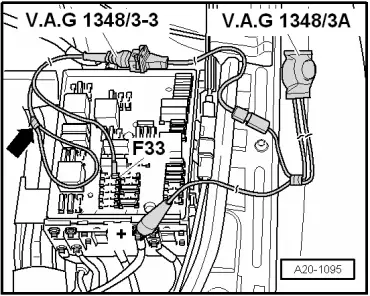

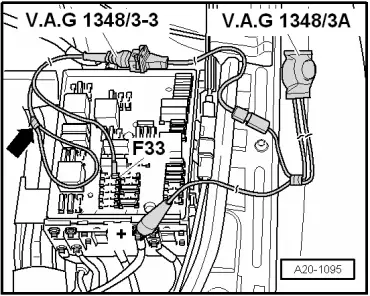

| Connect remote control for V.A.G 1348 -V.A.G 1348/3A- with adapter cable -V.A.G 1348/3-3- to right terminal of fuse socket F33. |

| –

| Tape off 2nd connector contact of the adapter cable -V.A.G 1348/3-3- with insulating tape -arrow- to prevent short circuits. |

| –

| Connect crocodile clip to vehicle battery (+). |

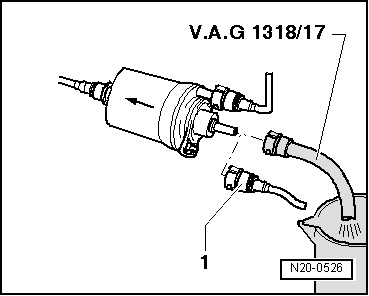

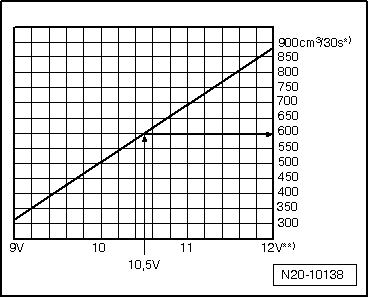

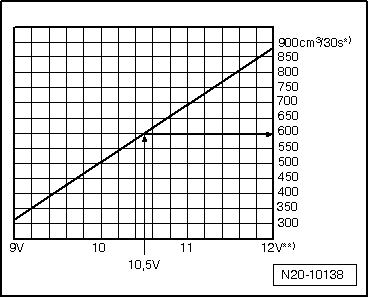

Note | Delivery rate of fuel pump must be measured at 4 bar. Therefore, test fuel pressure before measuring delivery rate. |

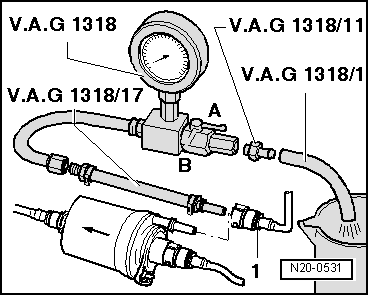

WARNING | Fuel system is under pressure! Wear eye protection and protective clothing to avoid possible injury and skin contact. Before loosening hose connections, wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note