Note | Observe environmental regulations for disposal. |

| –

| Remove securing bolts for sump to gearbox. |

| –

| Pull 3-pin connector off oil level and oil temperature sender -G266-. |

| –

| Loosen sump bolts on flywheel end using T-bar and socket, 10 mm -3185- and remove with Allen key, long reach -T10058-. |

| –

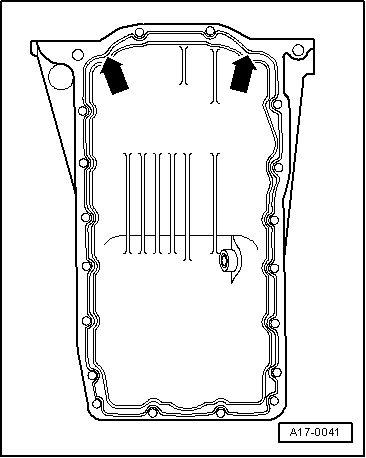

| Unscrew remaining bolts and remove sump. Loosen sump with light blows of a rubber headed hammer, if necessary. |

Note | t

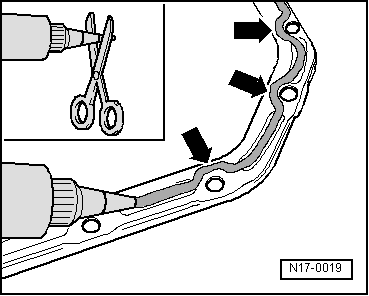

| Observe the use-by date of the sealing compound. |

| t

| The oil sump must be installed within 5 minutes of applying silicone sealing compound. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note