| –

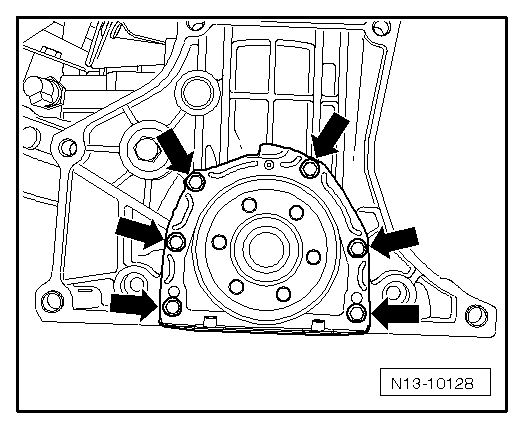

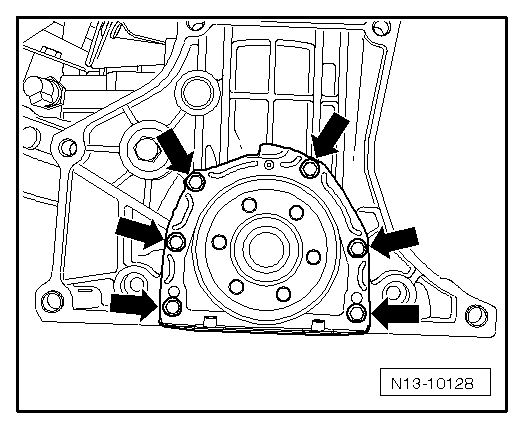

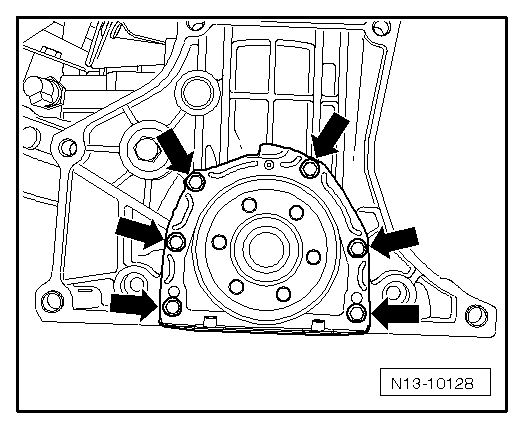

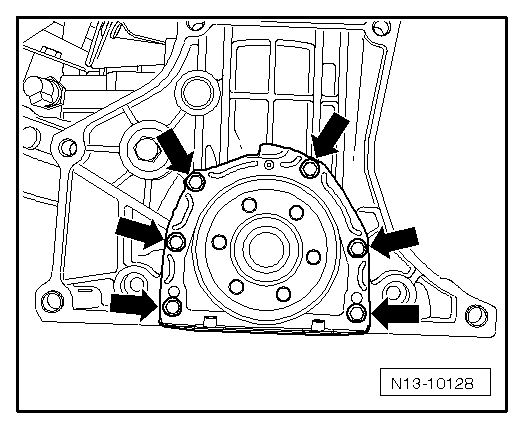

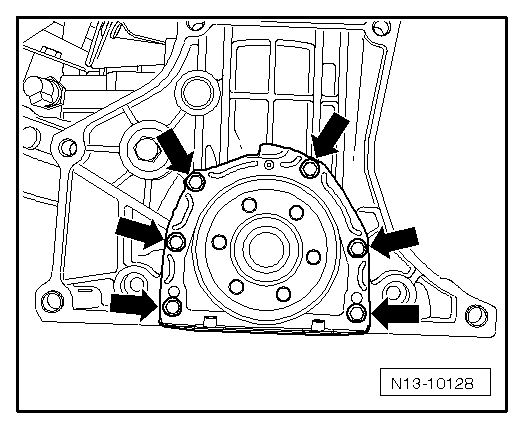

| Unbolt sealing flange -arrows-. |

| Installing sealing flange: |

| Characteristics of aluminium sealing flange: |

| t

| Centralising pins required for cylinder block |

| t

| Sealing lip in direction of engine |

| t

| Longer bolts than for plate sealing flange |

Note | t

| Do not additionally oil or grease the oil seal sealing lip. |

| –

| Clean sealing surfaces. They must be free of oil and grease. |

| –

| Remove oil residue from crankshaft journal using a clean cloth. |

| –

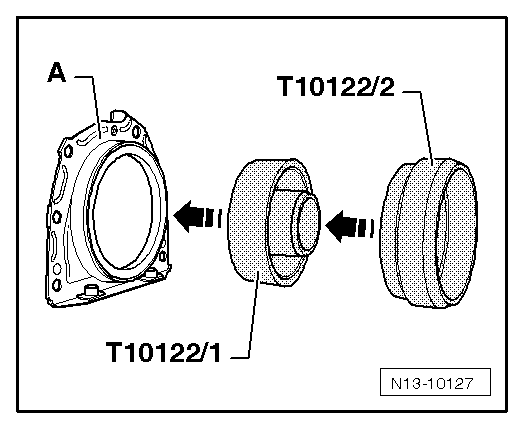

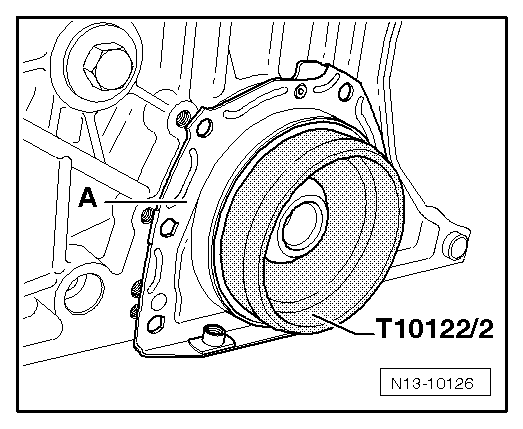

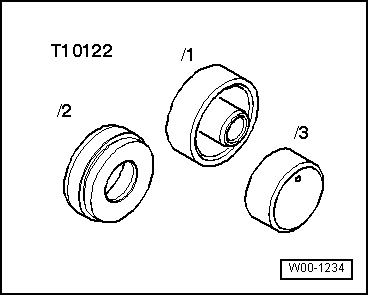

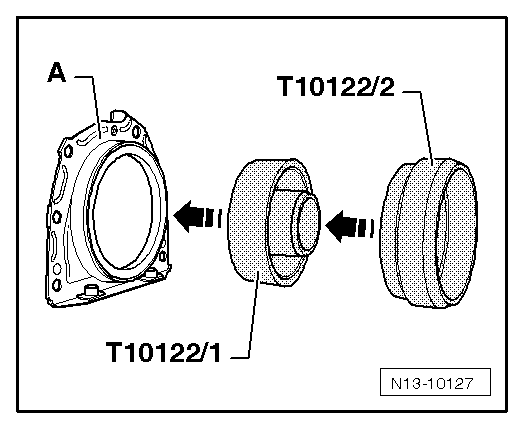

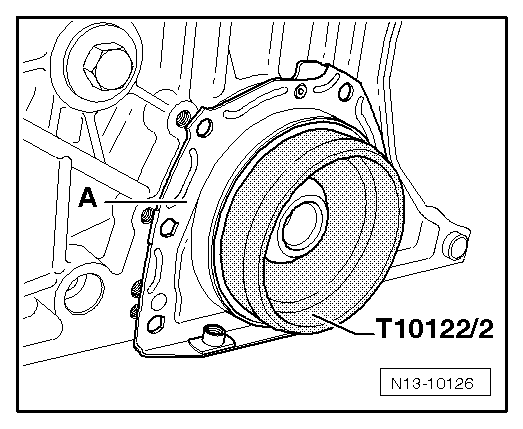

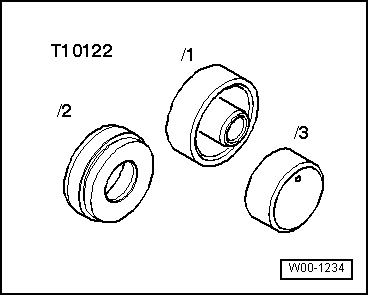

| Assemble fitting tool sleeves -T10122/1- and -T10122/2-. |

|

|

|

Note

Note

Note

Note