Golf Mk6

|

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

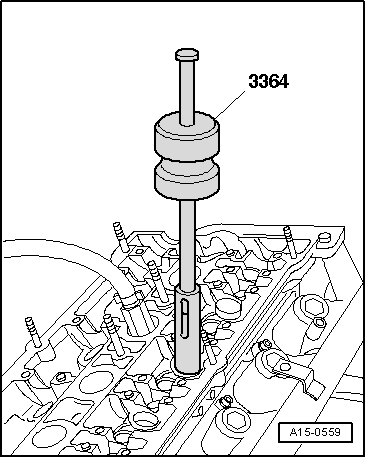

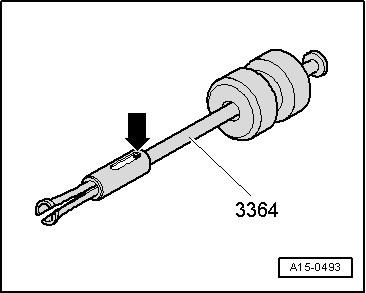

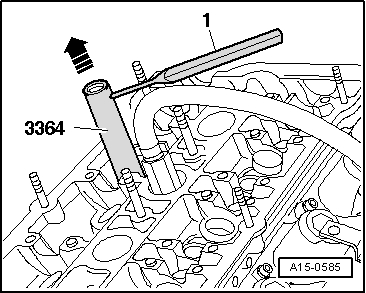

| t | Valve stem seal puller -3364- |

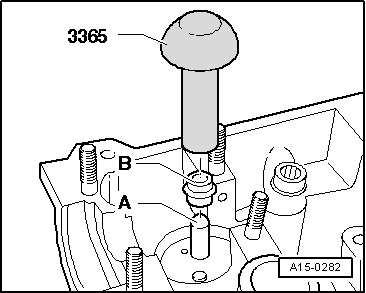

| t | Valve stem seal fitting tool -3365- |

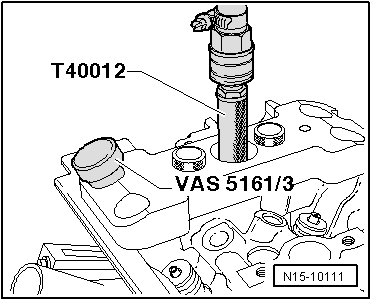

| t | Adapter -T40012- |

| t | Torque wrench -V.A.G 1331- |

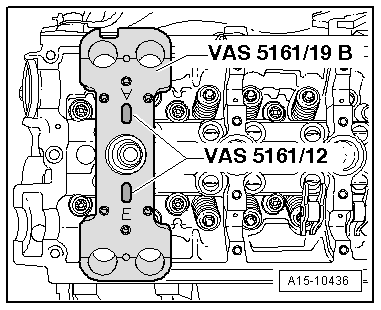

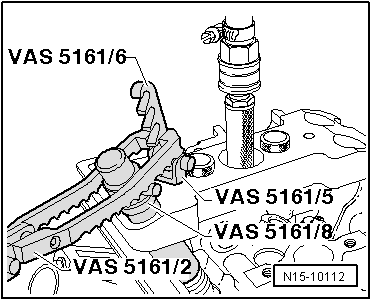

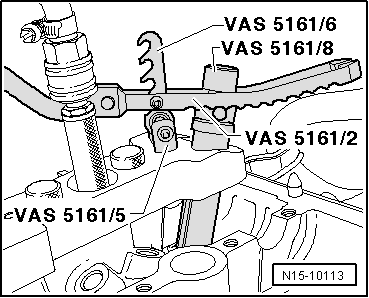

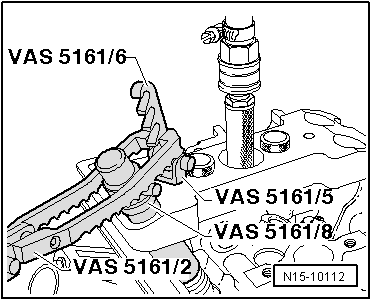

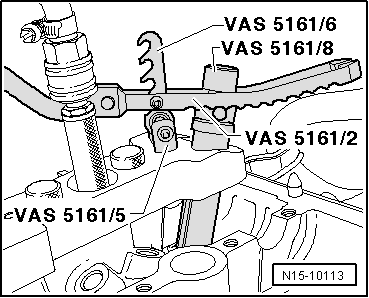

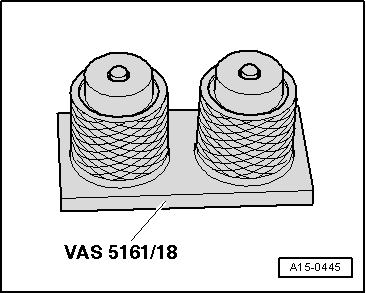

| t | Removal and installation device -VAS 5161- |

| t | Guide plate for 2.0 l and 3.0 l FSI engine -VAS 5161/19B- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|