Golf Mk6

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Specified torque | ||||

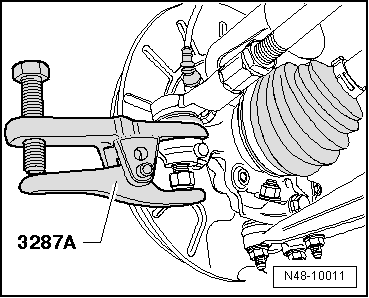

Swivel joint to cast steel suspension link

| 60 Nm | ||||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||||

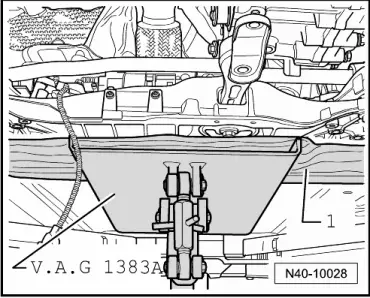

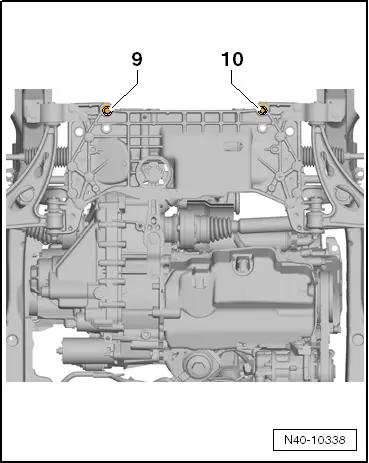

Subframe to body

| 70 Nm + 90° | ||||

Mounting bracket to body

| 70 Nm + 90° | ||||

Bracket to body

| 70 Nm + 90° | ||||

Anti-roll bar to coupling rod

| 65 Nm | ||||

Track rod ball joint to wheel bearing housing

| 20 Nm + 90° | ||||

Universal joint to steering box

| 30 Nm | ||||

| Exhaust system bracket to subframe → Engine; Rep. gr.26 | |||||

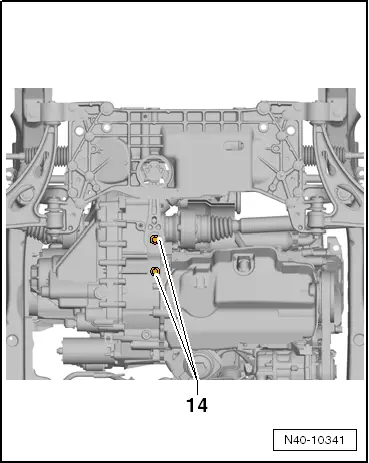

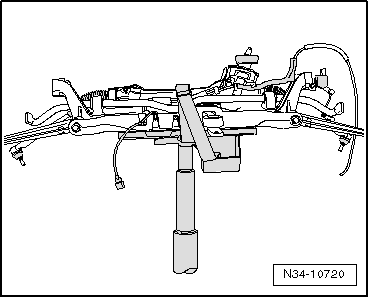

| Torque specifications for pendulum support to gearbox |

| Bolt | Specified torque | ||

M10 x 35

| 50 Nm + 90° further | ||

M10 x 75

| 50 Nm + 90° further |

Caution

Caution