| –

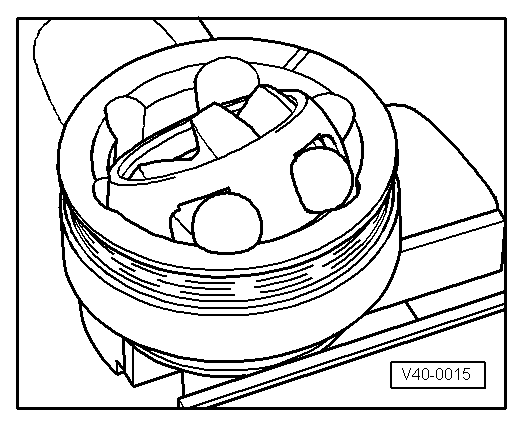

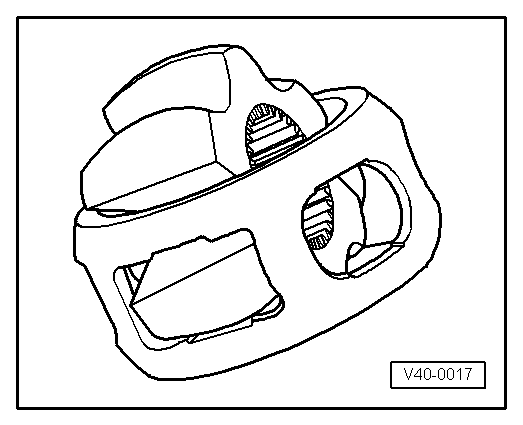

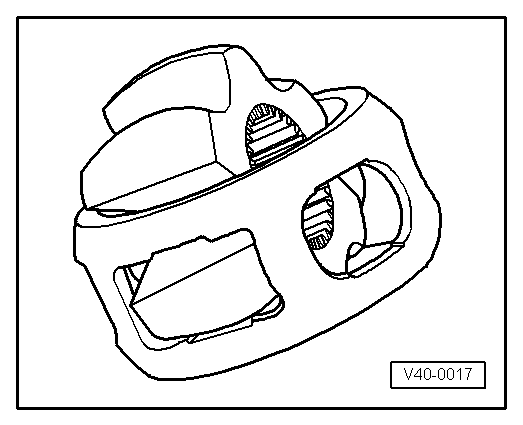

| Swing segment of hub into square cage window. |

| The six balls for each joint belong to a tolerance group. Check stub axle, hub, cage and balls for small indentations (pitting) and traces of seizing. Too much circumferential backlash in the joint becomes noticeable during load change jolts; in such cases, the joint must be renewed. Smoothing and traces of wear of the balls are no reason to change the joint. |

| –

| Pack half of total grease quantity (40 g) into joint body. |

| –

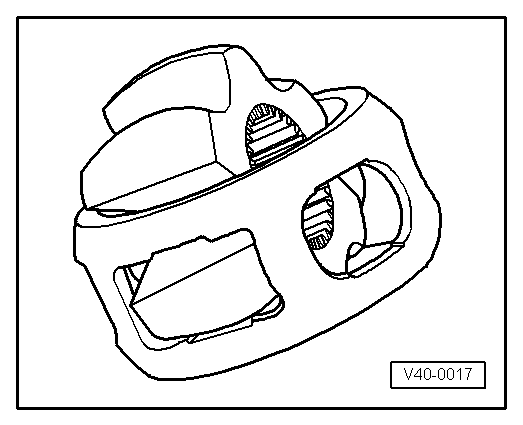

| Fit cage with hub into joint body. |

| –

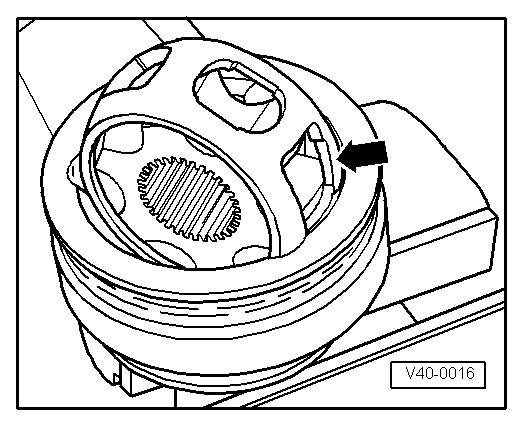

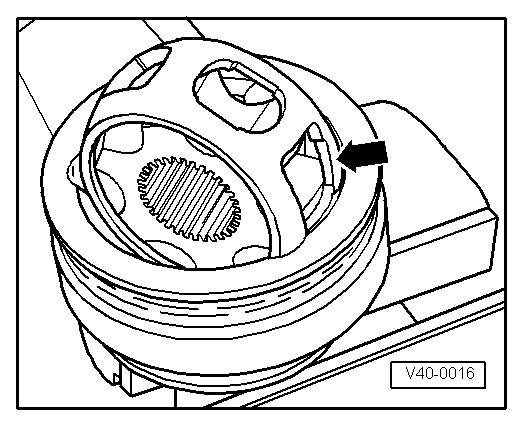

| Press in opposing balls one after the other; the original position of the hub relative to the cage and joint body must be restored. |

| –

| Fit new retaining ring into hub. |

| –

| Distribute remaining grease in boot. |

| –

| Checking function of constant velocity joint |

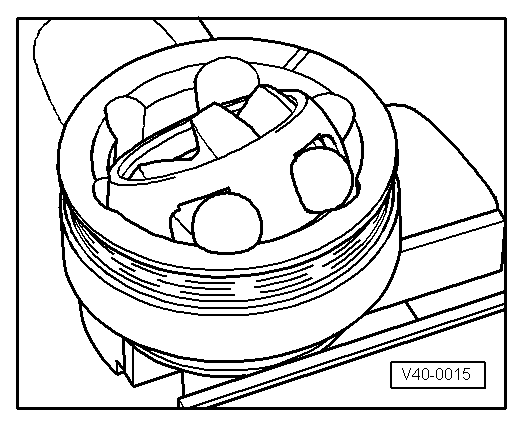

| The constant velocity joint is correctly assembled if the ball hub can be moved by hand backwards and forwards over its entire range of axial movement. |

|

|

|