Golf Mk6

| Repairing subframe |

| Special tools and workshop equipment required |

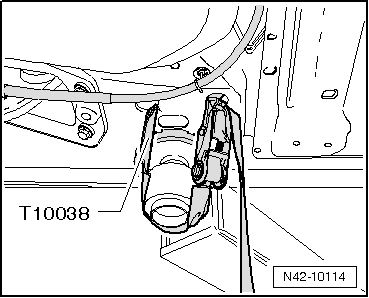

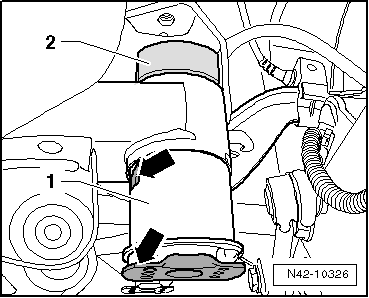

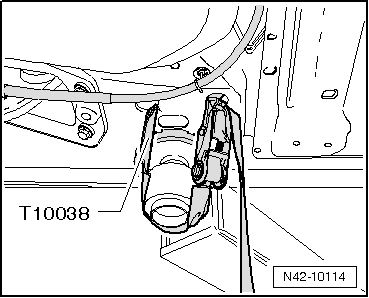

| t | Tensioning strap -T10038- |

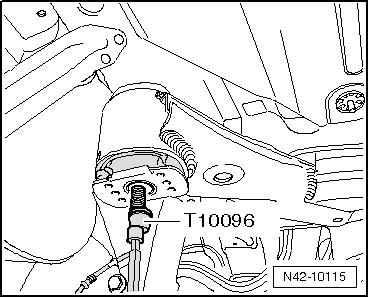

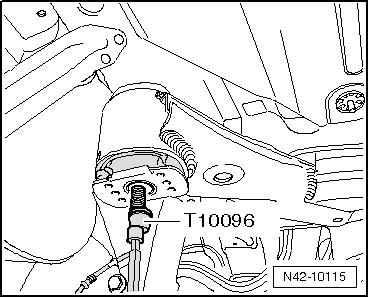

| t | Locating pins -T10096- |

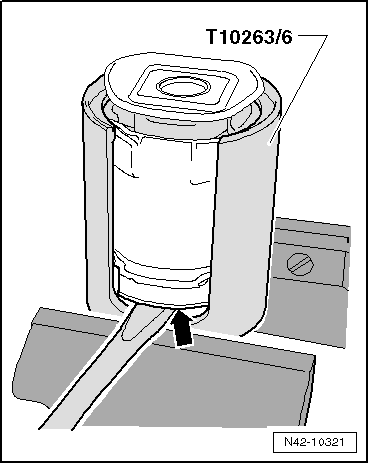

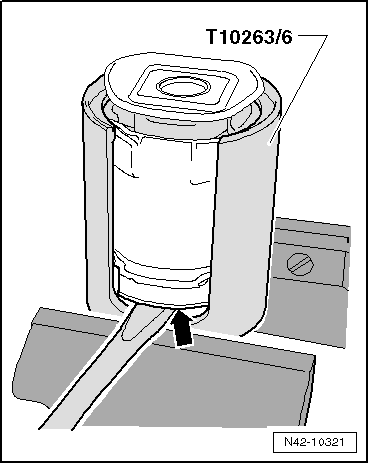

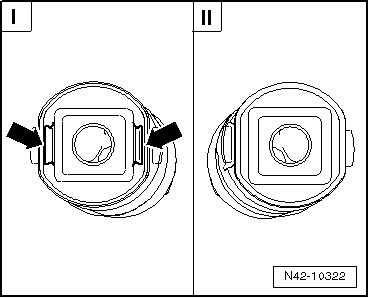

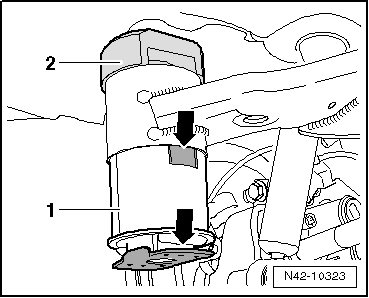

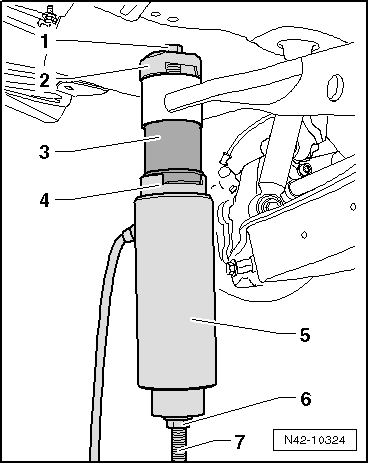

| t | Assembly tool -T10263- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Hydraulic press -VAS 6178- and thrust piece -T10205/13- |

| t | Foot pump -VAS 6179- |

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

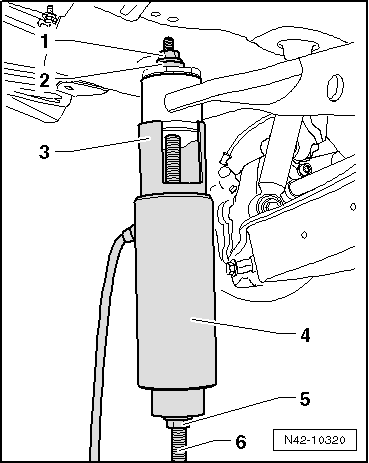

| Specified torques |

| Component | Specified torque | ||

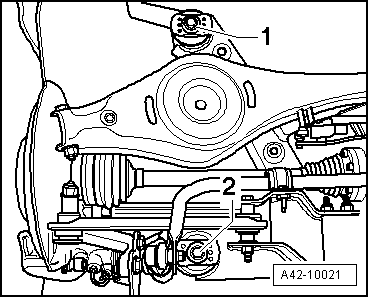

Subframe to body

| 90 Nm + 90° further |

WARNING

WARNING