| –

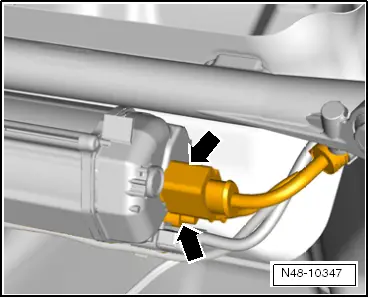

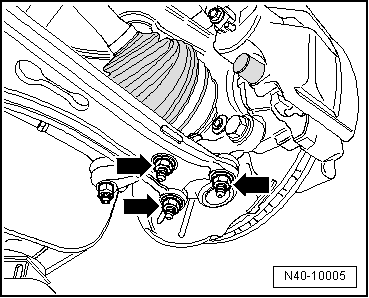

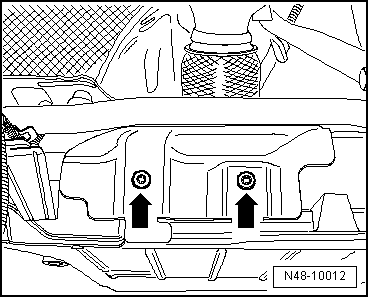

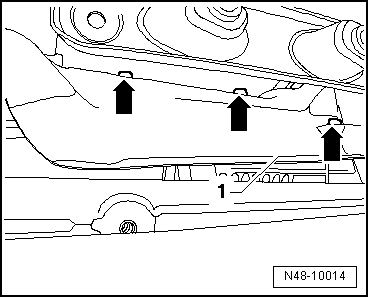

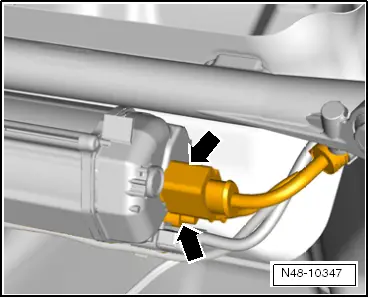

| Push on connectors -arrows- so that they engage audibly. |

Note | t

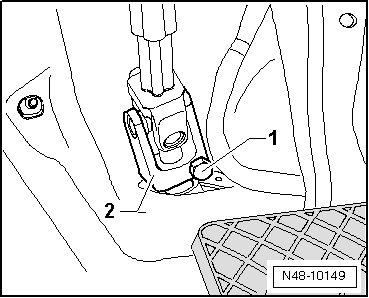

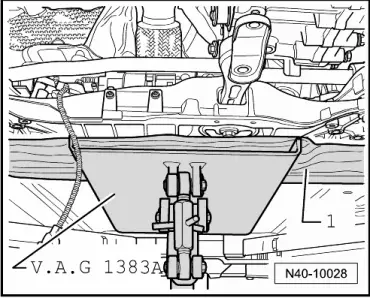

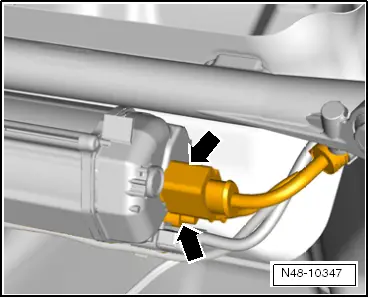

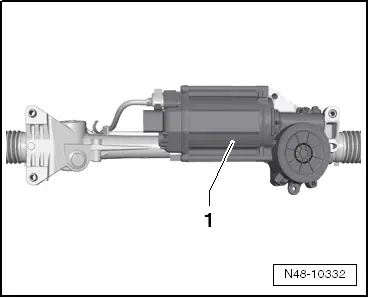

| Coat seal on steering box with suitable lubricant, e.g. soft soap, before installing steering box. |

| t

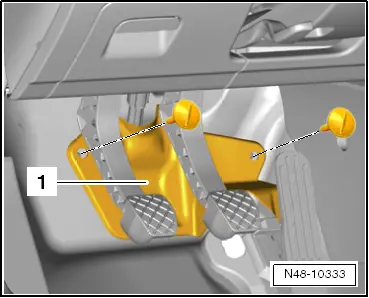

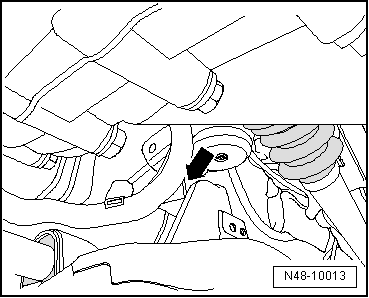

| After fitting the steering box to the jointed shaft, ensure that the seal is not kinked when lying against the assembly plate and that the opening to the footwell is correctly sealed. Otherwise, this can result in water leaks and/or noise. |

| t

| Ensure sealing surfaces are clean. |

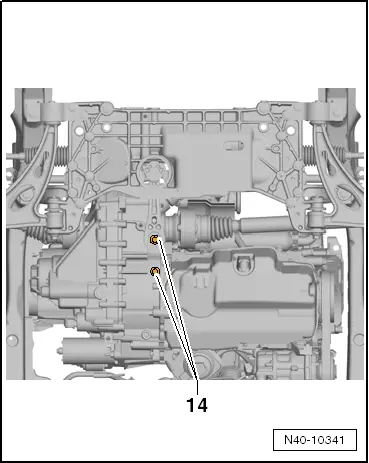

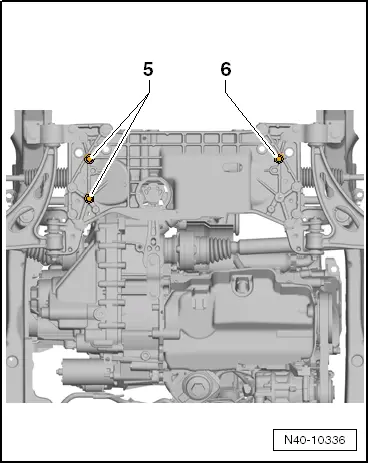

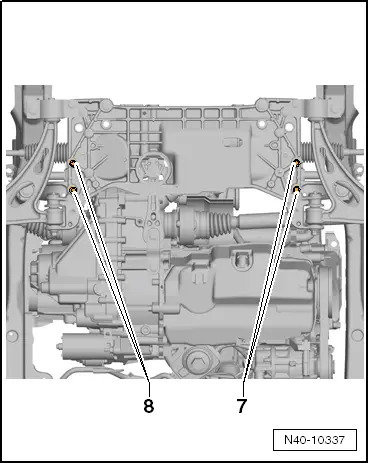

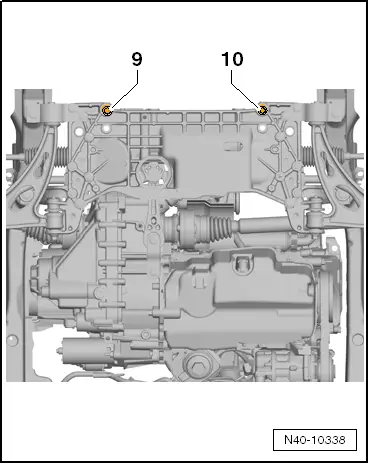

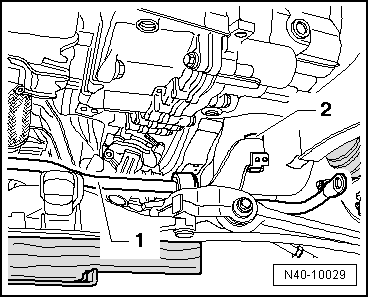

| Before inserting subframe bolts, position steering box on subframe and insert bolts for steering box and anti-roll bar. |

| –

| Connect electrical connections to steering box. |

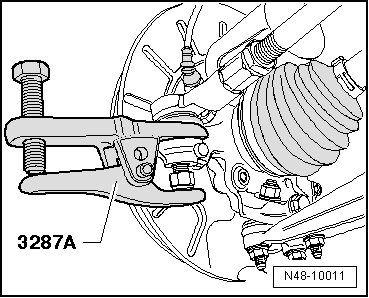

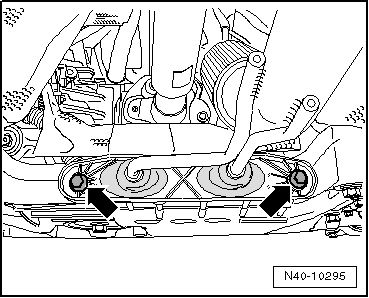

Note | Ensure that bellows are not damaged or twisted. |

| –

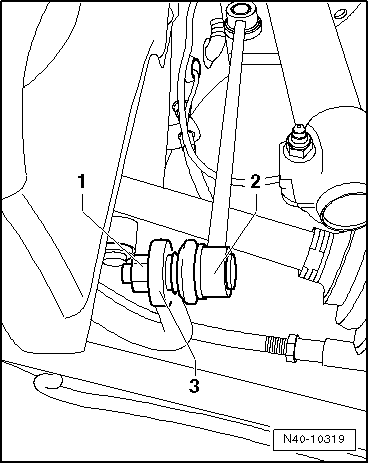

| Bolt universal joint to steering box. |

| –

| Carry out basic setting for steering angle sender -G85- using vehicle diagnosis, testing and information system -VAS 5051- → Vehicle diagnostic tester. |

| If new steering box has been installed, adapt electromechanical steering using vehicle diagnostic, testing and information system -VAS 5051-. |

| –

| Carry out adaption of electromechanical steering using vehicle diagnosis, testing and information system -VAS 5051- → Vehicle diagnostic tester. |

| Electromechanical power steering |

| 01 - System capable of self-diagnosis |

| Electromechanical steering system |

| Adapting electromechanical steering |

| After installation, check position of steering wheel during road test. |

| If steering wheel is crooked or a new steering box was installed, wheels must be aligned. |

|

|

|

Note

Note Note

Note

Caution

Caution