Passat (B3)

|

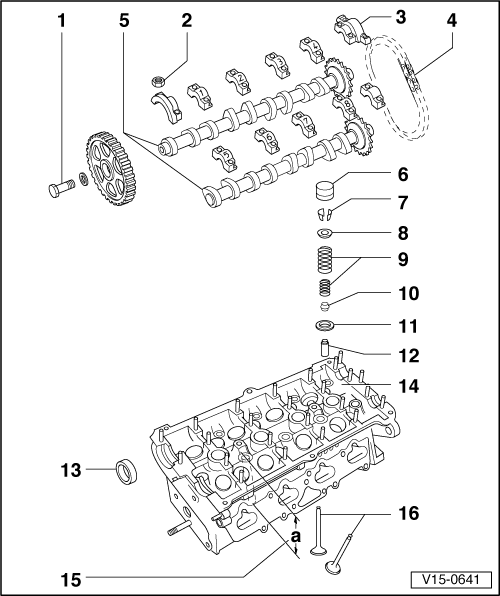

Servicing valve gear

Servicing valve gear

|

|

|

|

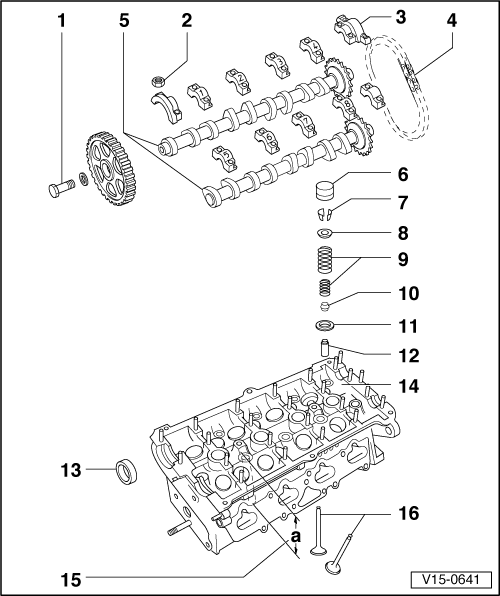

Note: Cylinder heads which have cracks between the valve seats or between valve seat inserts and the spark plug thread can be used further without reducing service life, provided the cracks do not exceed a maximum of 0.5 mm in width, or when no more than the first spark plug thread is cracked.

|

|

|

|

|

|

|

|

|

|

|

|

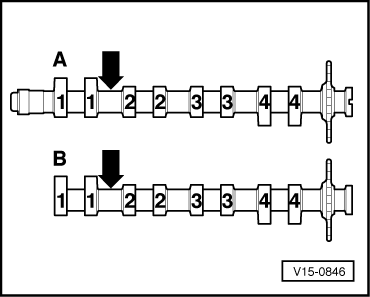

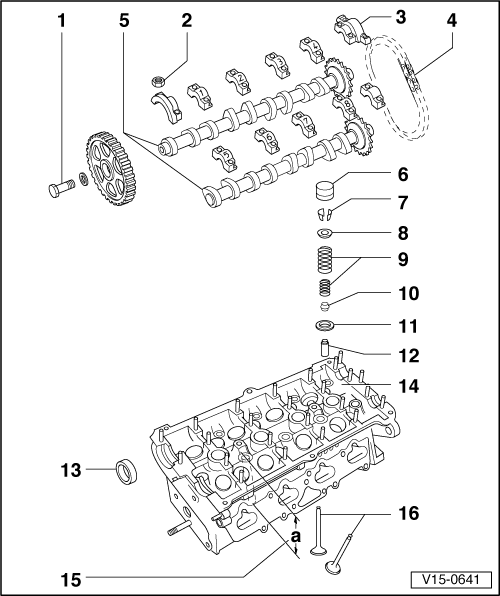

→ Fig. 2 Fitting position of camshaft bearing caps The recesses on the bearing caps must face towards intake side of cylinder head -arrow-. |

|

|||||||||||||||||||||

|

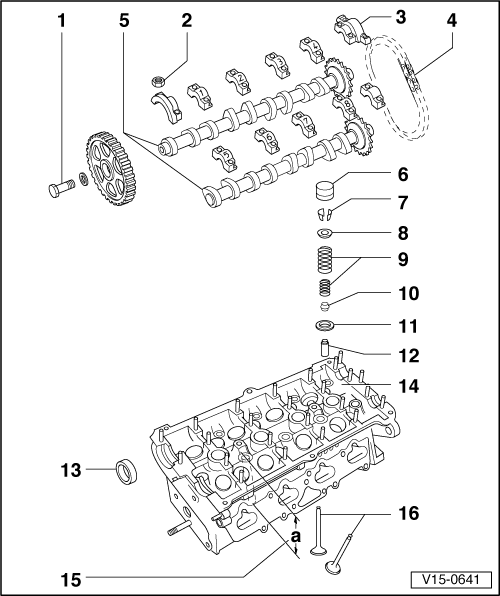

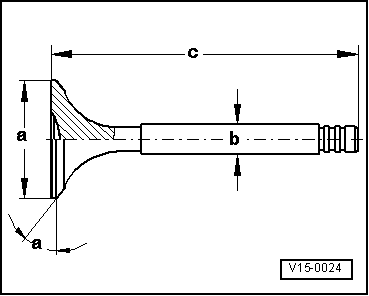

→ Fig. 4 Valve dimensions Note: Valves must not be reworked. Only lapping-in is permitted.

| |||||||||||||||||||||