-

‒ →

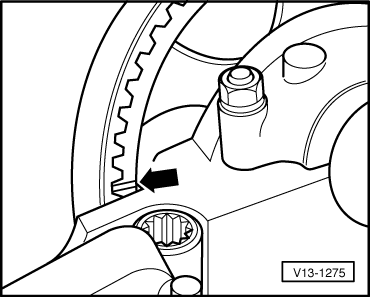

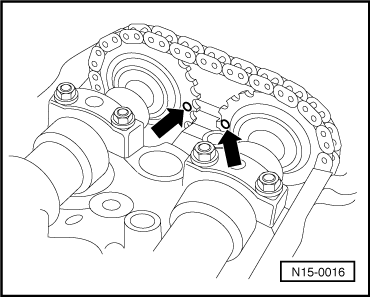

Install camshafts with chain so that the marks on the sprockets align -arrows-.

Notes:

-

◆ Observe D.O.R. marking.

-

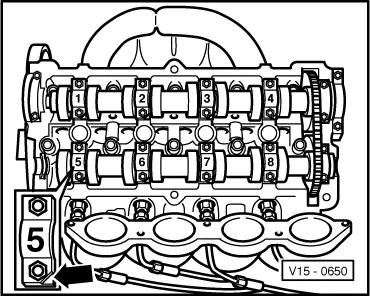

◆ When installing bearing caps ensure that the recesses on the caps face towards the intake side of the cylinder head -Fig. V15-0650-.

Inlet camshaft

-

‒ Tighten bearing caps 6 and 8 alternately and

diagonally to

15 Nm.

-

‒ Install remaining bearing caps and tighten to

15 Nm.

Exhaust camshaft

-

‒ Tighten bearing caps 2 and 4 alternately and

diagonally to

15 Nm.

-

‒ Lightly coat bearing cap contact surface on camshaft sprocket and on distributor cap with sealing compound AMV 174 004 01.

-

‒ Install remaining bearing caps and tighten to

15 Nm.

-

‒ Install camshaft sprocket and tighten to

65 Nm

(counter-hold with 3036).

The rest of the assembly is basically a reverse of the dismantling sequence.

Installing toothed belt and adjusting timing

.

Note:

When new tappets have been installed the engine must not be started for about 30 minutes. Hydraulic compensation elements must settle (otherwise valves will strike pistons).

|