Passat (B3)

|

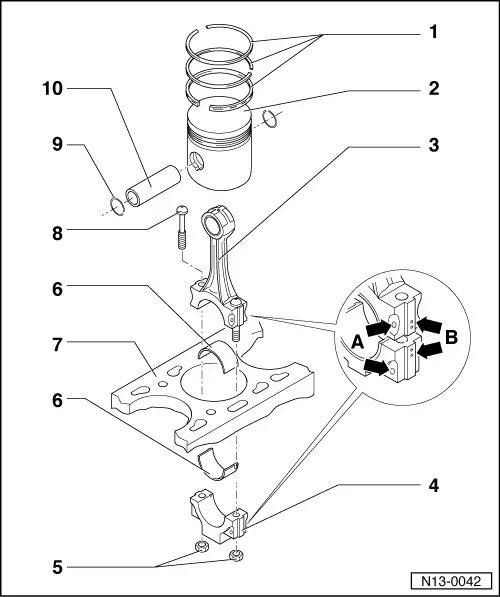

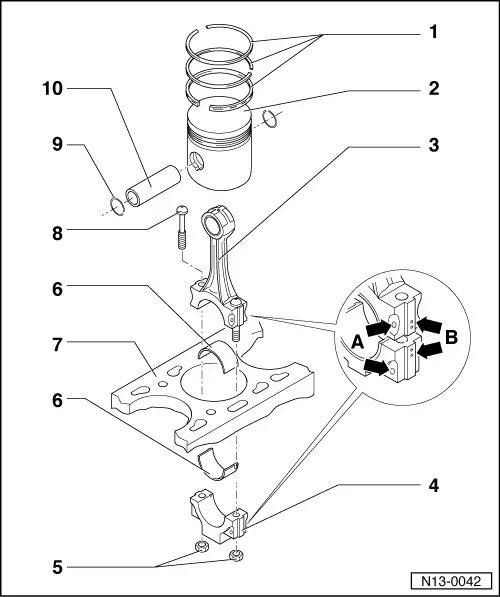

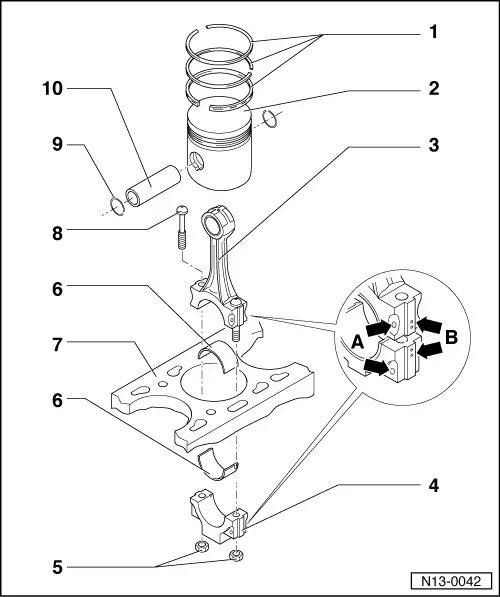

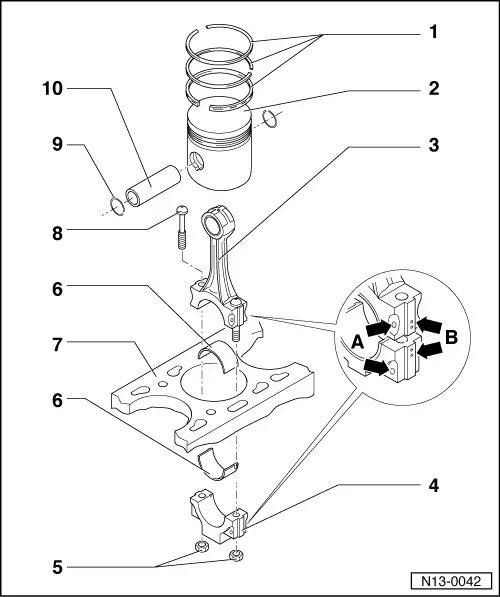

Dismantling and assembling pistons and conrods

Dismantling and assembling pistons and conrods

|

|

|

|

|

|

|

|

|

|

|

Special tools, testers and auxiliary items

|

|

|||||||||||||||||

|

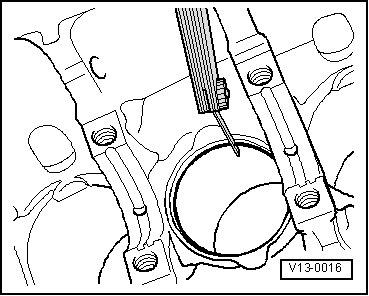

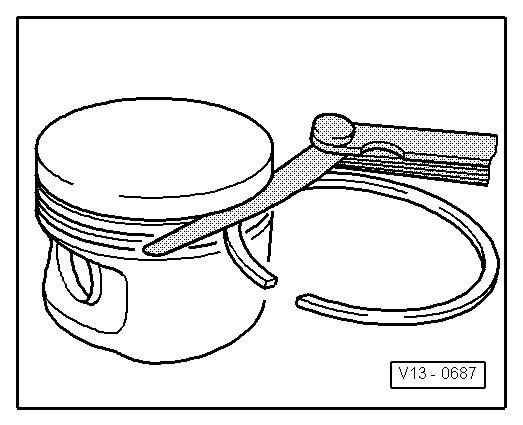

→ Fig. 2 Checking ring to groove clearance Clean groove before check.

| |||||||||||||||||

|

|

|

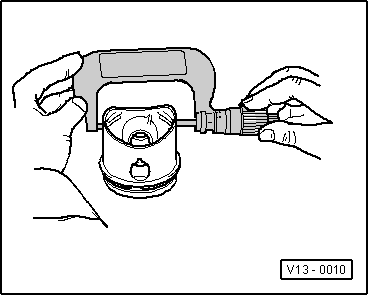

→ Fig. 3 Checking piston Measure pistons approx. 10 mm from the lower edge of skirt, at 90 ° to the piston pin axis. Deviation from nominal dimension |

|

||||||||||||||||

|

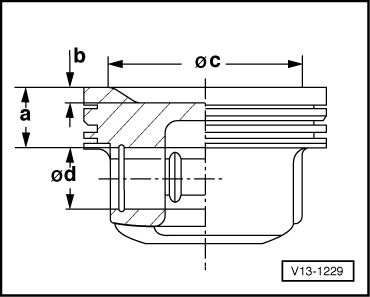

→ Fig. 4 Piston characteristics

When repairing an engine only pistons and piston rings of the same type and pistons with the same weight class may be installed. | ||||||||||||||||

|

|

|

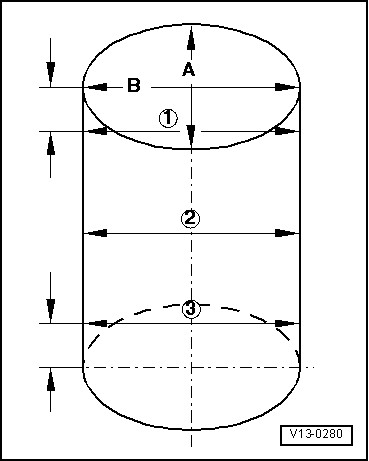

→ Fig. 5 Checking cylinder bores

Note: Measuring the cylinder bores must not be done when the cylinder block is mounted on a repair stand with adapter bracket VW 540, as incorrect measurements would then be possible. |