Passat (B3)

|

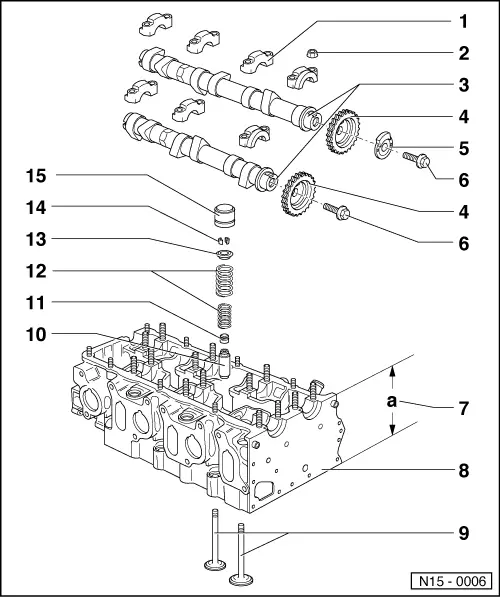

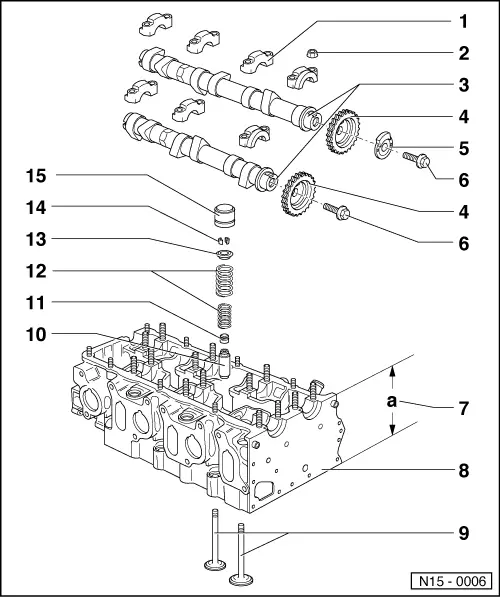

Servicing valve gear

Servicing valve gear

|

|

|

|

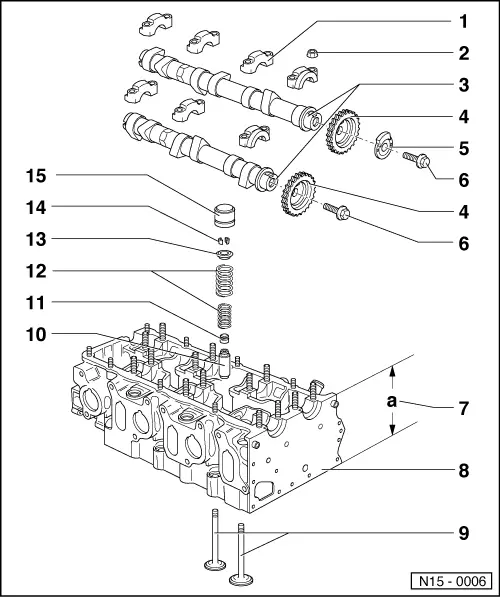

Note: Cylinder heads which have cracks between the valve seats or between valve seat inserts and the spark plug thread can be used further without reducing service life, provided the cracks do not exceed a maximum of 0.5 mm in width. |

|

|

|

|

|

|

|

|

|

|

|

|

|

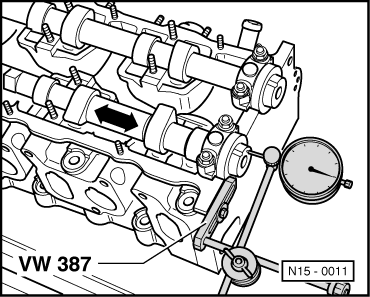

→ Fig. 1 Camshafts, checking axial clearance Wear limit: max. 0.15 mm Check with bucket tappets removed and with first and last bearing caps fitted to appropriate camshaft. |

|

|

|

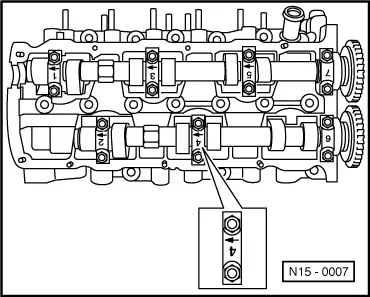

→ Fig. 2 Fitting position of camshaft bearing caps The bearing cap identification must be readable from the exhaust side of the cylinder had and the arrow pointing to vibration damper end. |

|

|||||||||||||||||||||

|

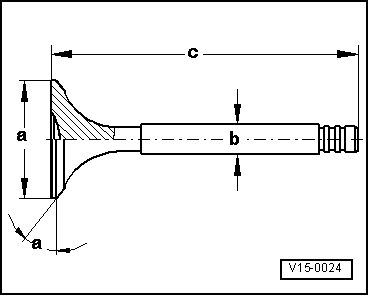

→ Fig. 3 Valve dimensions Note: Valves must not be reworked. Only lapping-in is permitted.

| |||||||||||||||||||||