|

Servicing Diesel direct injection system

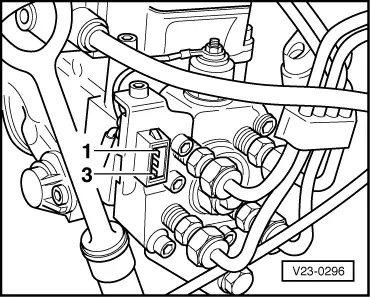

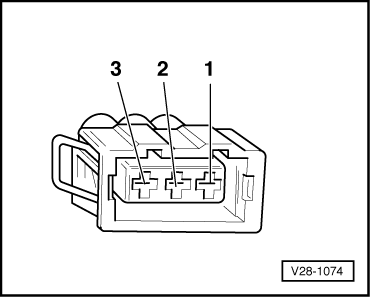

Checking injection adjuster control range

The control range of the injection adjuster can be checked with help of final control element test and at the same time calling-up measured value block 04. To do this it is required to activate the control element Commencement of injection valve -N108 and then exiting the final control element test with key -C-. Using this sequence the commencement of injection valve continues to be pulsed so that with help of measured value block 04 (display zone 3) the injection adjuster control range can be read.

Special tools, testers, measuring instruments and auxiliary items required

-

◆ Fault reader V.A.G 1551 or vehicle system tester V.A.G 1552 with cable V.A.G 1551/3

-

◆ Test box V.A.G 1598/18

-

◆ Hand multimeter V.A.G 1526 or multimeter V.A.G 1715

-

◆ Adapter set V.A.G 1594

-

◆ Current flow diagram

Test sequence

-

‒ Connect fault reader V.A.G 1551 and select engine electronics control unit (address word 01); selection is carried out with engine idling.

|