Passat (B3)

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

|||||||||

|

Note: If something different is indicated on the display: => Fault reader operating instructions

If the specifications are not attained:

Continuation of check when display = always 0: |

|

|

Display 1:

Display 0:

If no fault in wire is detected:

Continuation of check when display = always 1: |

|

|

Display 0:

Display 1:

|

|

|

If no wiring fault is detected:

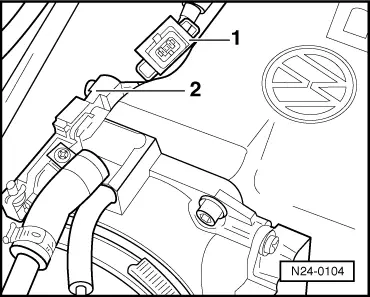

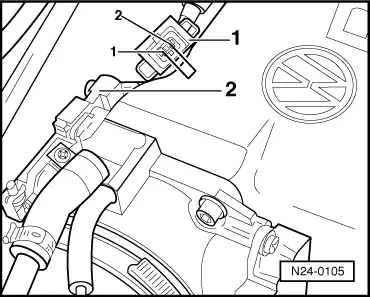

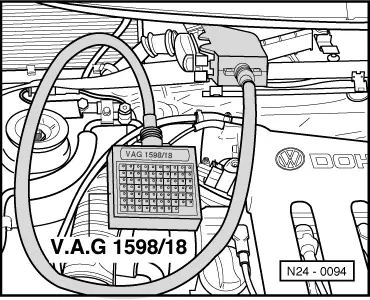

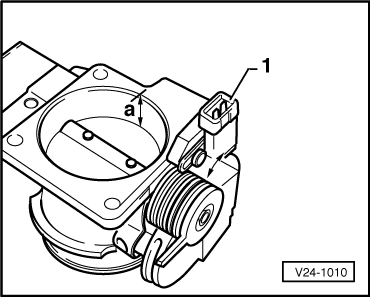

Renewing idling switch Special tools, testers and auxiliary items

Work sequence

|

|

|

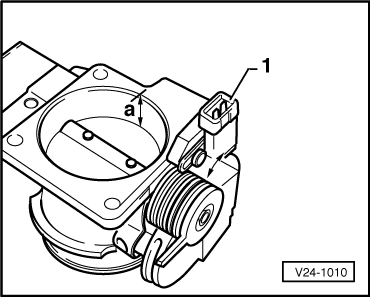

Note: Setting the throttle valve must be carried out very carefully. On no account must the dimension -a- be exceeded. Adjusting idling switch Special tools, testers and auxiliary items

Work sequence |

|

|

Note: The throttle valve adjustment must be carried out very carefully. On no account must the adjusting dimension -a- be exceeded. |