Polo Mk3

|

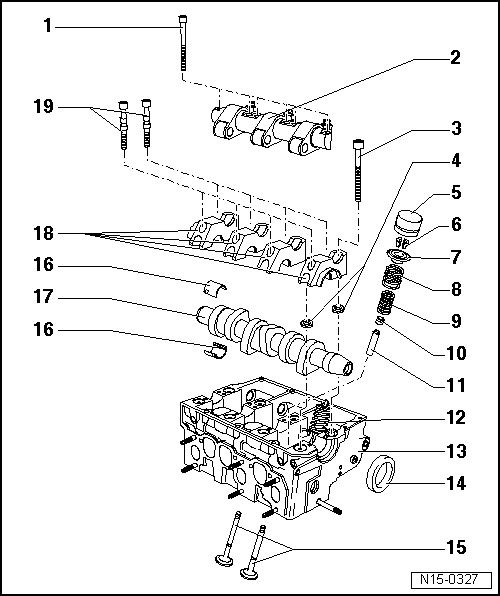

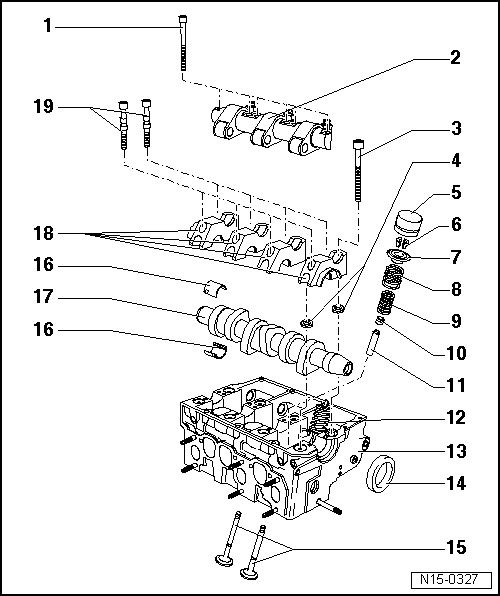

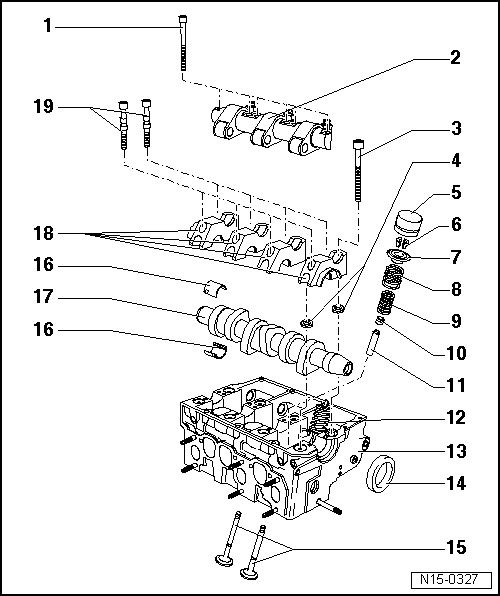

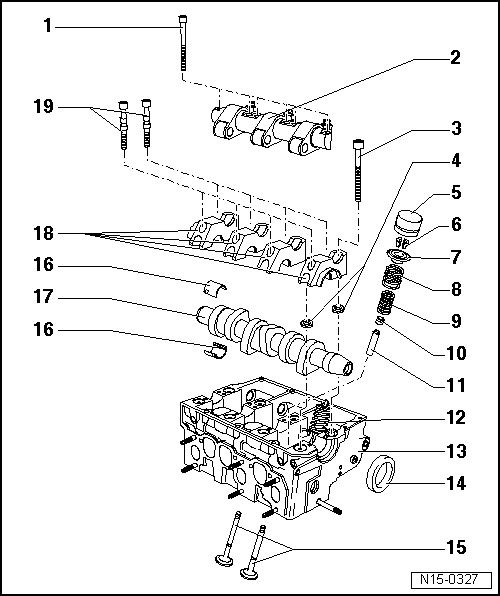

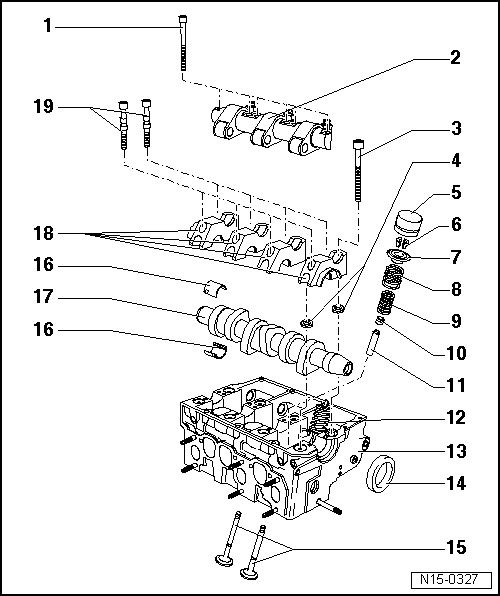

Servicing valve gear

Servicing valve gear

|

|

|

|

|

|

|

|

|

=> Repair group 23; Servicing diesel direct injection system; Removing and installing unit injectors |

|

|

|

|

|

|

|

|||||||||||||||||||||

|

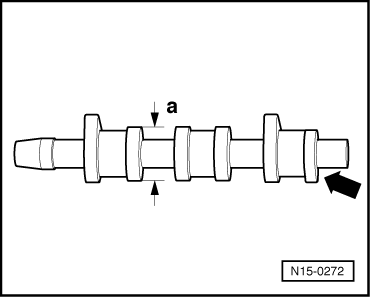

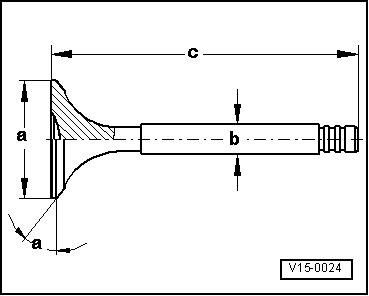

→ Fig. 3 Valve dimensions Note: Valves must not be reworked. Only lapping-in is permitted.

| |||||||||||||||||||||