Polo Mk3

|

Removing and installing gearbox

Removing and installing gearbox

|

|

|

|

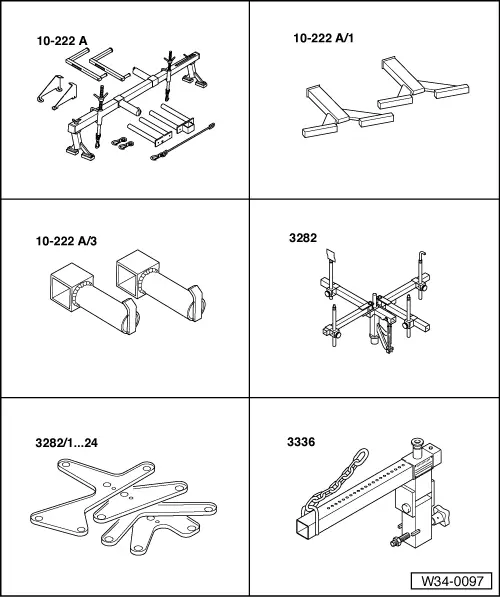

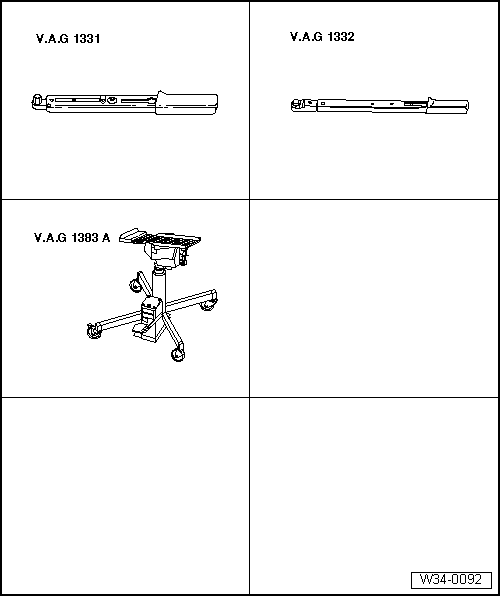

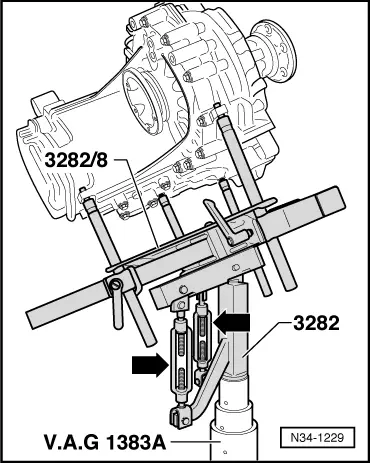

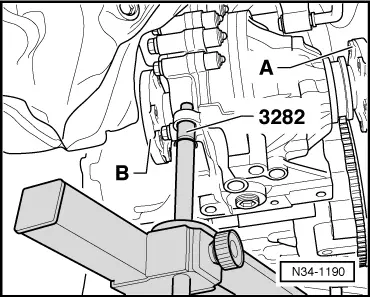

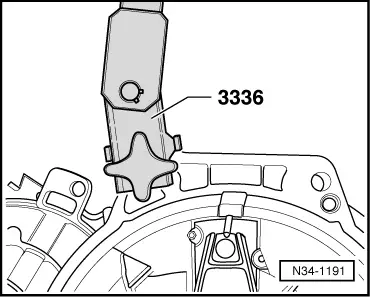

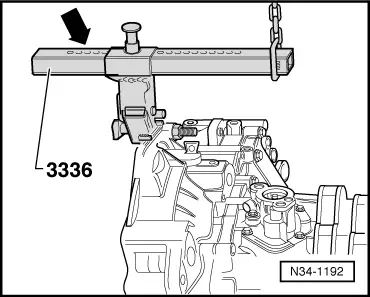

Special tools and workshop equipment required

|

|

|

|

Special tools and workshop equipment required

Removing

|

|

|

|

|

|

|

|

|

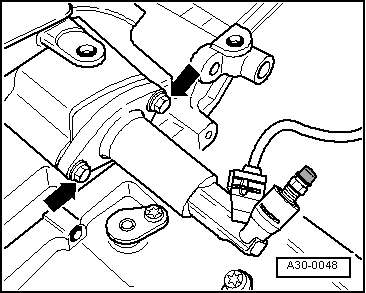

Note: Do not depress clutch pedal.

|

|

|

|

|

|

|

|

|

=> Repair group 27; Removing and installing starter.

|

|

|

|

|

|

|

|

|

|

|

|

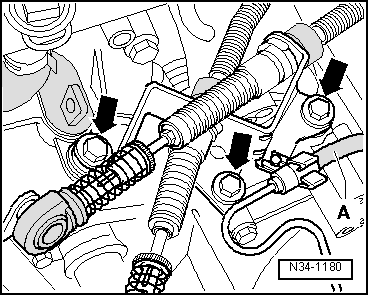

Note: Ensure the sump does not lie against the assembly mounting when lowering the engine/gearbox assembly. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

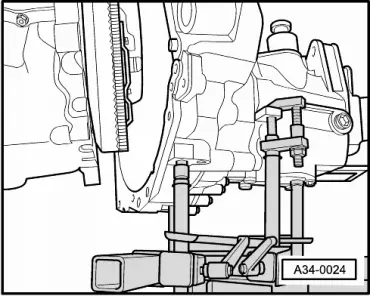

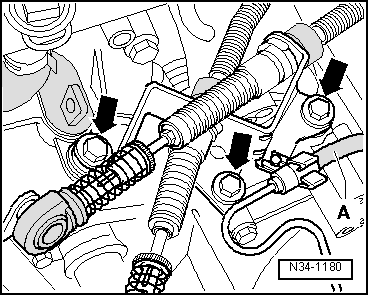

Note: Do not damage P.A.S pipe when lowering gearbox. |

|

|

|

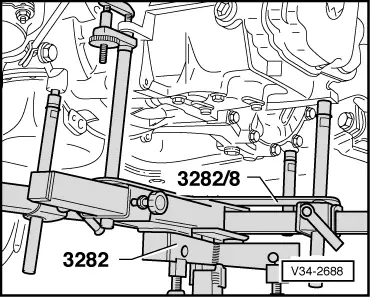

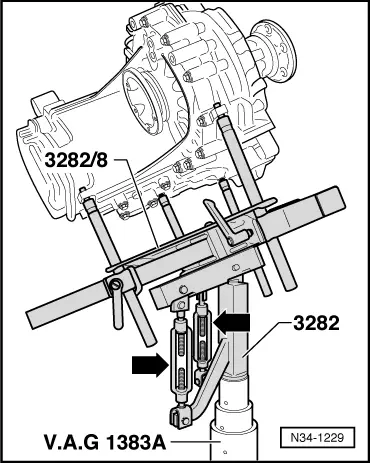

Transporting the gearbox

|

|

|

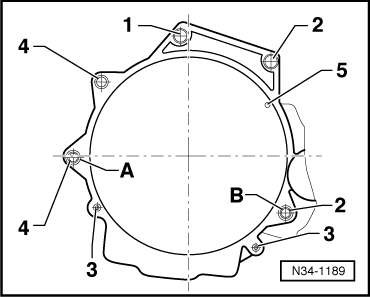

No. of holes visible = 5 |

|

|

|

Installing Notes:

|

|

|

The clutch plate must be able to slide lightly to and fro on the input shaft.

|

|

|

|

|

|

|

|

|

Note: Do not damage P.A.S pipe.

|

|

|

|

|

|

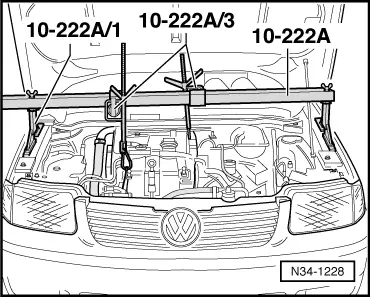

Warning!

Do not remove support bar 10-222A until the bolts securing the left-hand gearbox console have been tightened to torque setting.

|

|

|

=> Repair group 26; Removing and installing parts of the exhaust system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

=> General body repairs, exterior; Repair group 55; Bonnet

Note: Note radio coding for vehicles with coded radio.

Tightening torques |

|

|||||||||||||||||||||||||

|

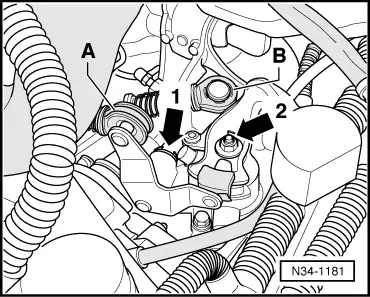

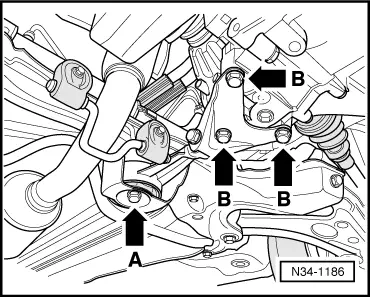

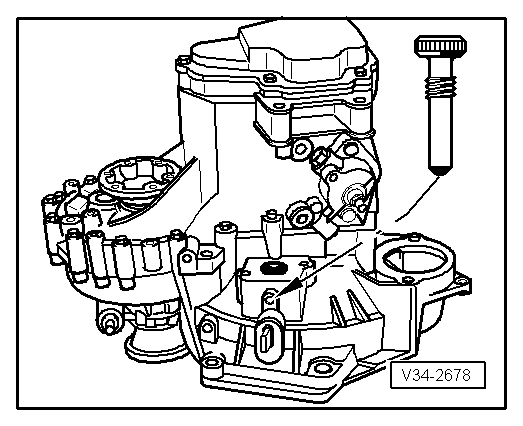

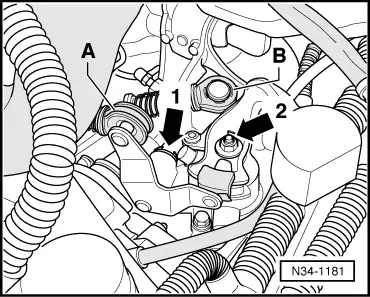

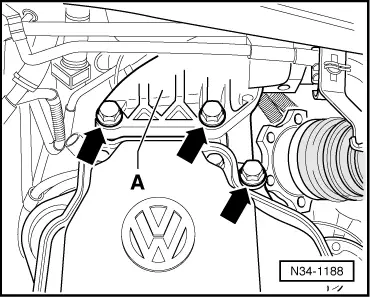

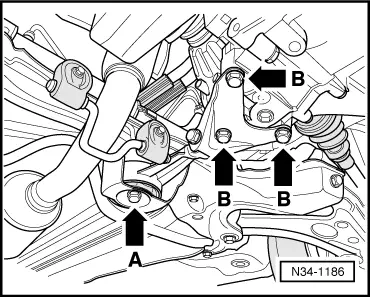

→ Gearbox to engine

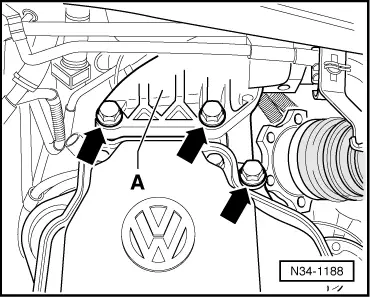

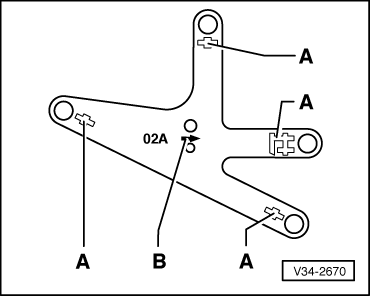

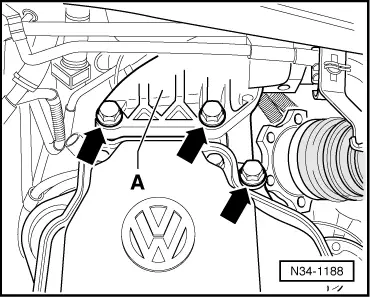

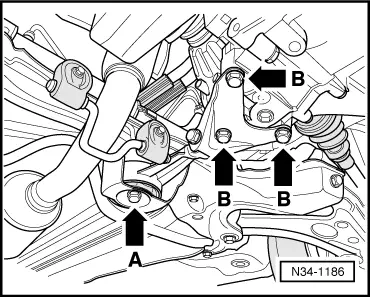

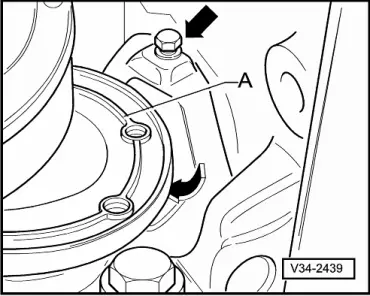

1) Stud with drive 2) Also starter to gearbox 3) Small cover plate for flywheel Items A + B - Dowel sleeves |

|

||

|

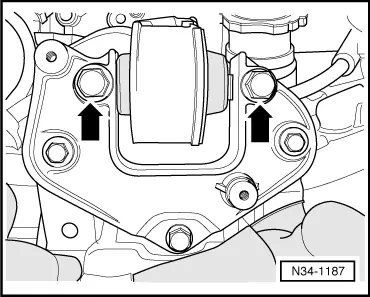

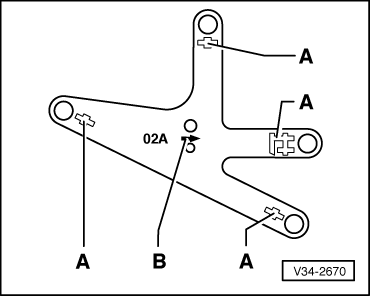

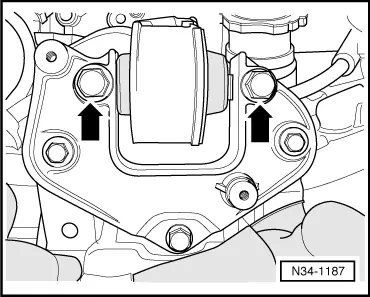

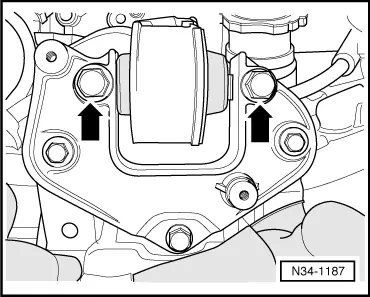

→ Gearbox console -A- to gearbox

|

|

||

|

→ Gearbox to body

|

|

||||||||||||||||

|

→ Rear gearbox mounting

Note: Install engine/gearbox mountings stress-free. => Repair group 10; Removing and installing engine.

| ||||||||||||||||