Polo Mk3

|

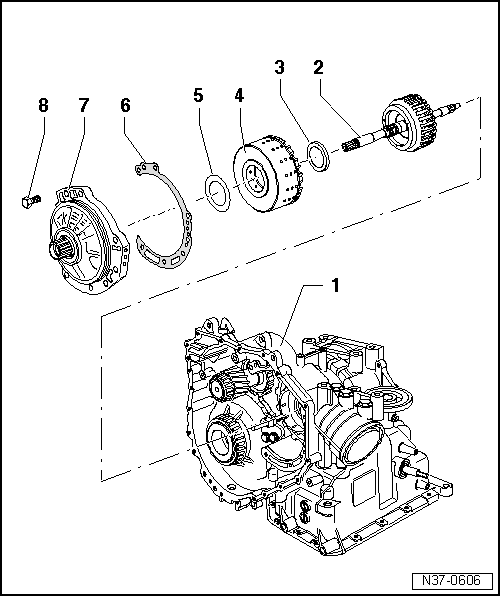

Dismantling and assembling gearbox

Adjusting clutch play

|

|

|

|

|

|

|

|

|

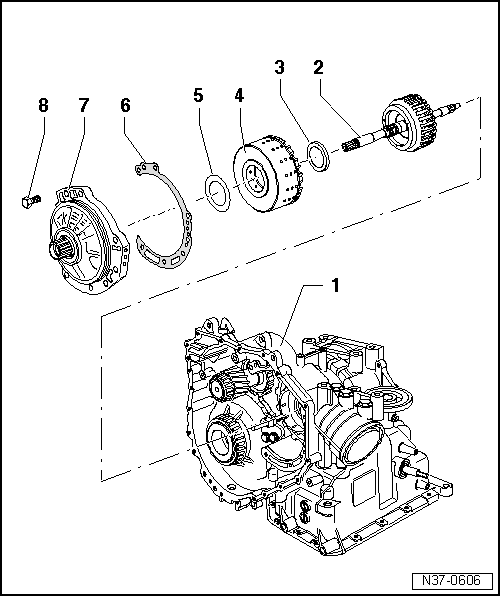

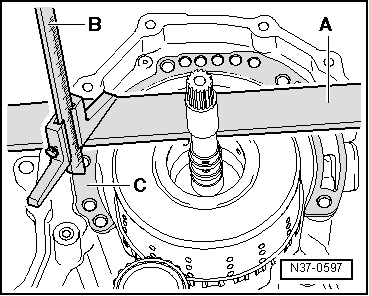

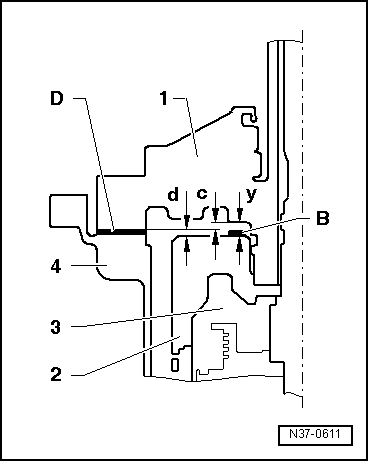

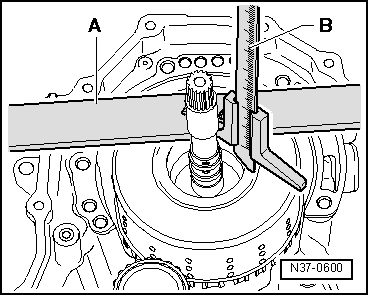

Adjusting clutch play between -K1- and ATF pump → Calculate thickness for the axial needle bearing -A- The thickness of the axial needle bearing is determined by the gap "x" and is to be selected from the table, => Page 37-159 . Gap x = a - b A - Axial needle bearing (not installed when performing measurement). D - Gasket 1 - ATF pump 2 - Reverse gear clutch -K2- 3 - 1st to 3rd gear clutch -K1- |

|

|

|

4 - Gearbox housing Calculating "a":

Example: Reading 1 = 54.8 mm

|

|

|||||||||

Example: Reading 2 = 23.2 mm

Calculating "b": |

|

|

|

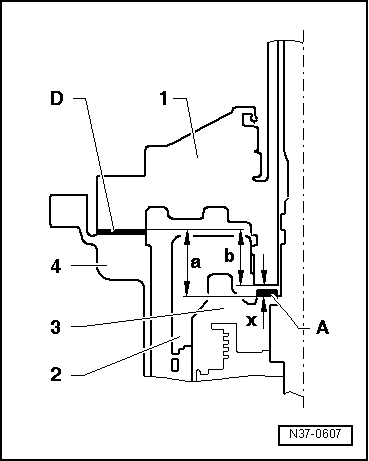

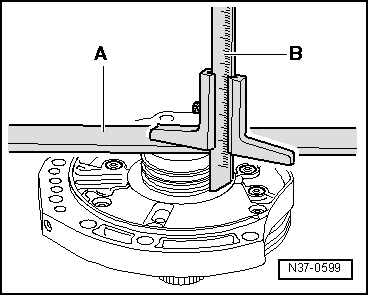

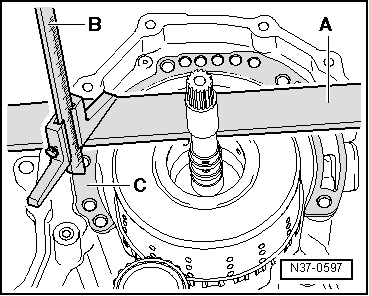

Adjusting clutch play between -K2- and ATF pump → Calculate thickness of shim -B- Shim thickness is determined by gap "y" and selected from table, => Page 37-163 . Gap y = c + d B - Shim (not installed when performing measurement). D - Gasket 1 - ATF pump 2 - Reverse gear clutch -K2- 3 - 1st to 3rd gear clutch -K1- |

|

|

|

4 - Gearbox housing Calculating "b":

Example: Reading 1 = 34.0 mm |

|

|||||||||

Example: Reading 2 = 33.8 mm

|

|

|

|

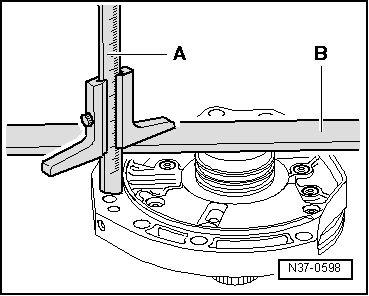

Calculating "d":

Example: Reading 1 = 88.5 mm |

|

||||||||||||||

Example: Reading 2 = 23.2 mm

Gap y = c + d = 0.2 mm + 1.5 mm = 1.7 mm

Table of "Shims":

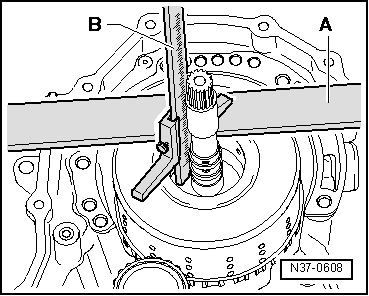

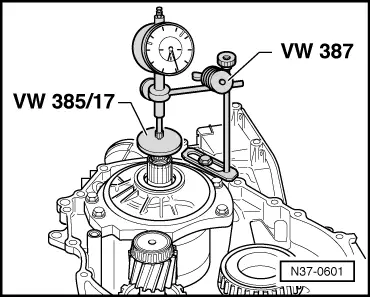

Check measurement (clutch play)

|

|

|

|