Polo Mk3

|

Servicing injection system

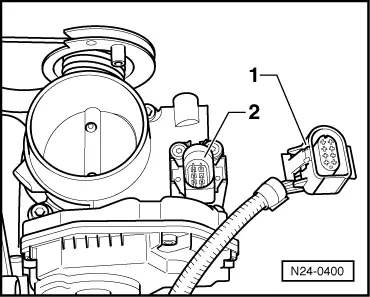

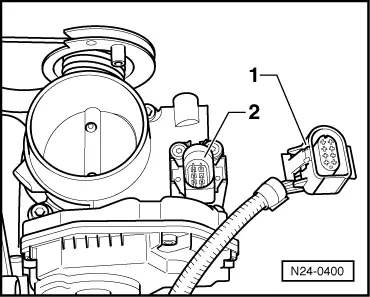

Checking throttle valve control part

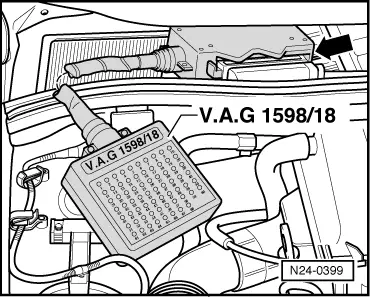

Note: If the throttle valve control part (J338) is removed and installed or replaced the basic setting must be performed . Special tools, testers, measuring instruments and auxiliary items required

Checking idling switch

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

|||||||||

If the specifications are not obtained:

Continuation of check when display is always at 1 |

|

|

Display 0:

Display 1:

|

|

|

|

If the voltage supply and wirings are OK: Continuation of check when display constantly shows 0

Display 1:

Display 0:

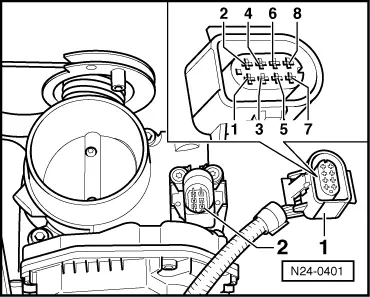

If the voltage supply and wirings are OK: Checking throttle valve positioner and throttle valve positioner potentiometer Test conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

||

If the specification is not obtained: |

|

|

If no fault is detected:

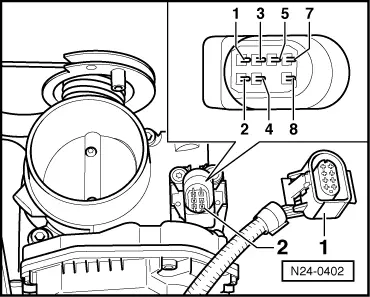

Checking throttle valve potentiometer Test conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

|||||||||

If the figure does not increase uniformly:

If the display constantly shows 0 <° or is above 90 <°:

Continuation of check when display 0 <°: |

|

|

Display above 90 <°:

Display 0 <°:

If the voltage supply and wirings are OK: Continuation of check when display is above 90 <°: |

|

|

Display 0 <°:

Display above 90 <°:

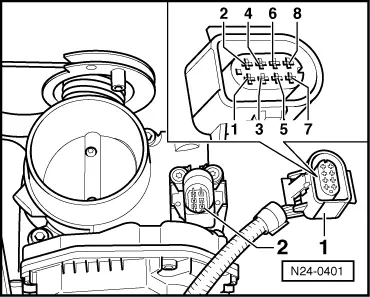

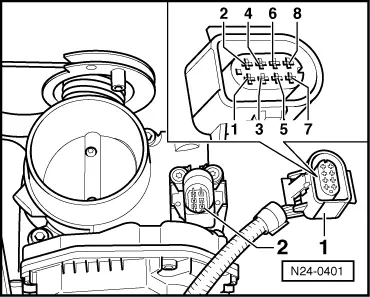

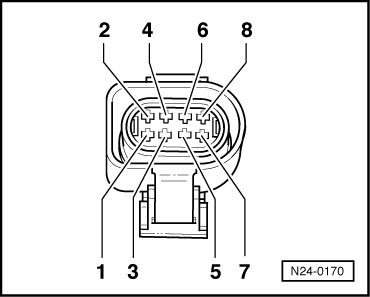

If the voltage supply and wirings are OK: Checking voltage supply and wiring to control unit |

|

|

|

|

|

|

|

|

If no wiring fault is detected:

|