| –

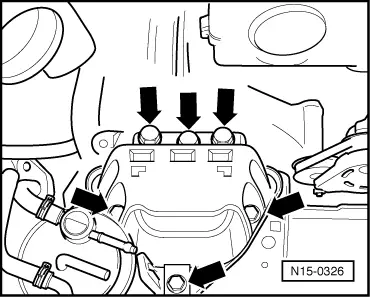

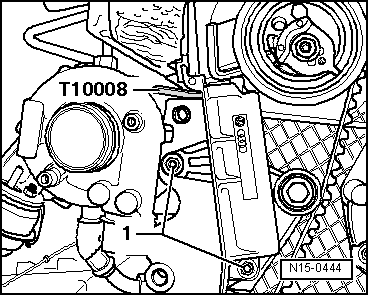

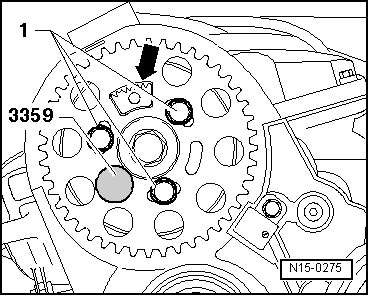

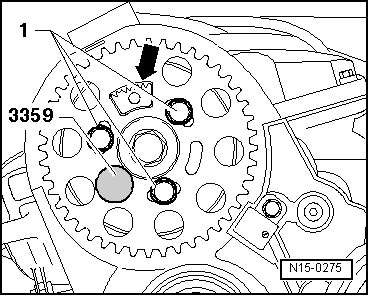

| Tighten securing bolts -1- of camshaft pulley to 25 Nm. |

| –

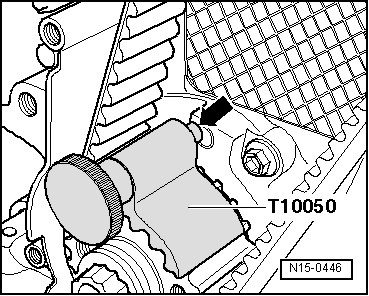

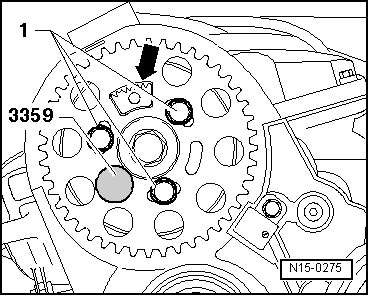

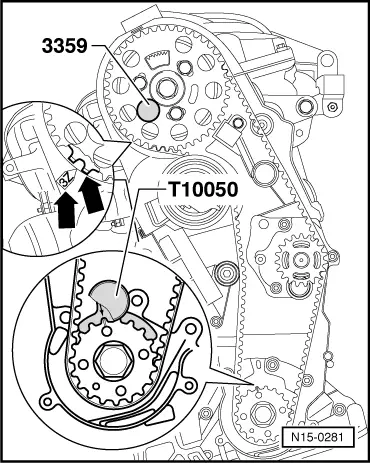

| Remove locking pin for diesel injection pump -3359- and crankshaft stop -T10050-. |

| –

| Turn crankshaft two rotations in engine direction of rotation and set again to TDC No. 1 cylinder. |

Note | t

| When doing this, the pin of the crankshaft stop -T10050- must engage in the sealing flange from the rotational movement. |

| t

| If the crankshaft is turned past TDC No. 1 cylinder and the crankshaft stop -T10050- could not engage in the sealing flange, turn the crankshaft back 1/4 turn to be able to turn the crankshaft in engine direction of rotation again to set it to TDC No. 1 cylinder. Corrections to the position by turning against engine direction of rotation in order to insert the crankshaft stop -T10050- are not permissible. |

| –

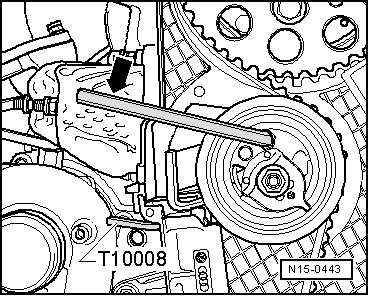

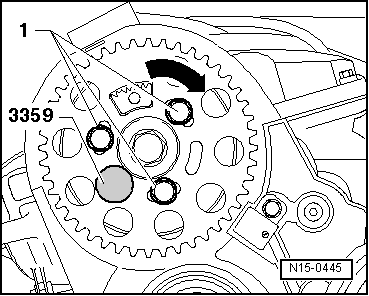

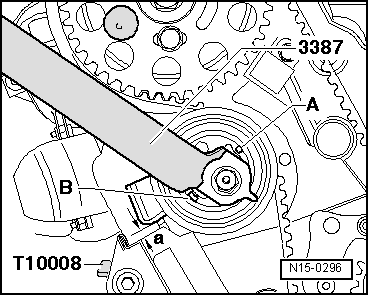

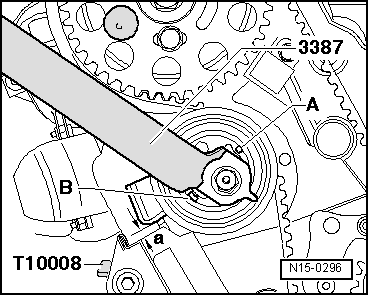

| Once the crankshaft stop -T10050- has engaged, check whether: 1. dimension -a- is reached and 2. the hub can be locked using locking pin for diesel injection pump -3359-. |

| If dimension -a- is not attained: |

| –

| Tension the tensioning roller again. To do this, hold tensioning roller with 2-hole pin wrench -3387-, loosen securing nut and release force of tensioning device until dimension -a- is attained. |

| Specification dimension -a-: 4 ± 1 mm |

| –

| Tighten securing nut to 20 Nm and 45° (1/8 turn) further. |

| If the hub cannot be locked: |

| –

| Pull the crankshaft stop -T10050- pin out of the drilling in the sealing flange and turn the crankshaft until the hub can be locked with the locking pin for diesel injection pump -3359-. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note